Cadmium Zinc Telluride Wafer: Pricelist & Key Information for Buyers

When it comes to high-performance materials, Cadmium Zinc Telluride Wafer stands out as an excellent choice for various applications. I understand how important it is to find reliable suppliers, which is why I’m excited to present our top-quality wafers tailored to your needs. As a B2B purchaser, you're probably looking for competitive pricing and quick access to a comprehensive pricelist. Our Cadmium Zinc Telluride Wafers are not only competitively priced but also come with detailed specifications to ensure they meet your project requirements. Customer satisfaction is my priority, and I'm here to help you through the buying process. Whether you have specific volume needs or just want to explore options, connecting with us can lead to excellent project outcomes. Let’s simplify your procurement journey and make sure you get the best value. Your satisfaction and success mean everything to us! Ask for our pricelist today and see how we can support your business goals.

Cadmium Zinc Telluride Wafer Products Stands Out

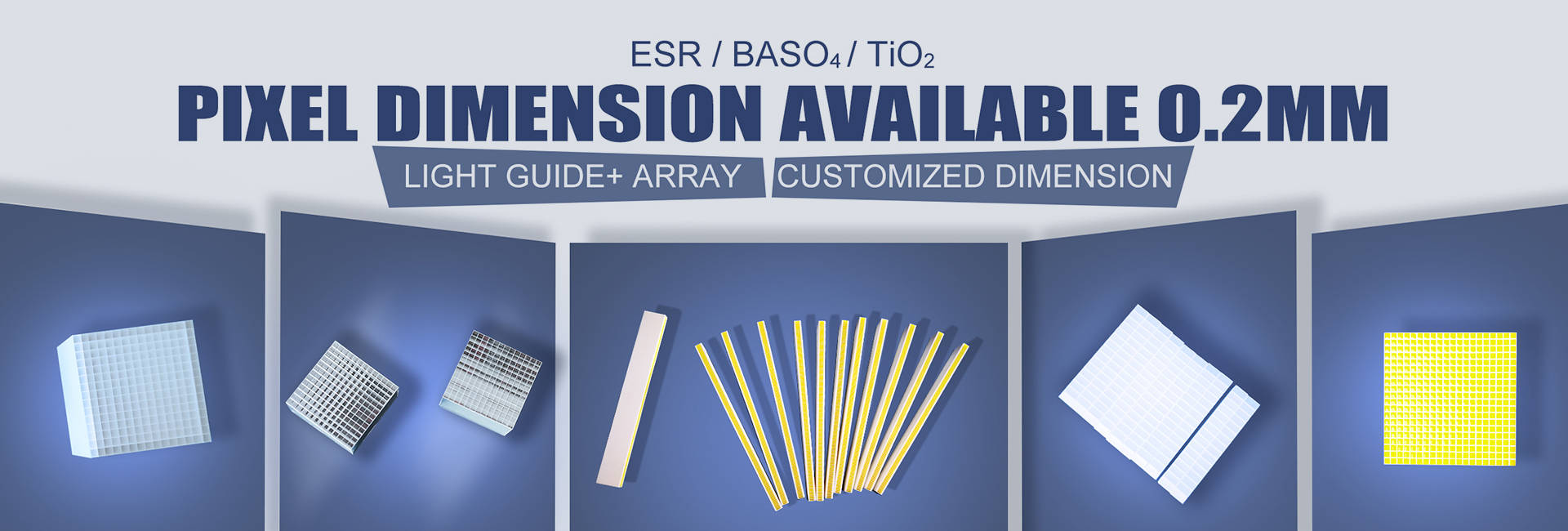

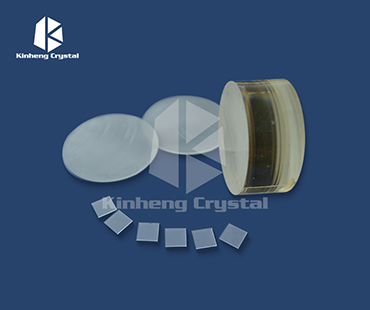

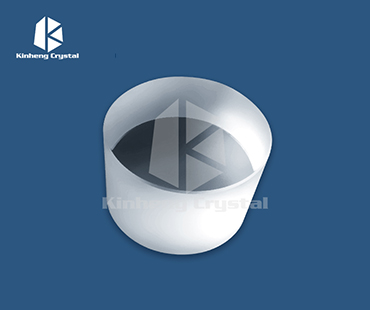

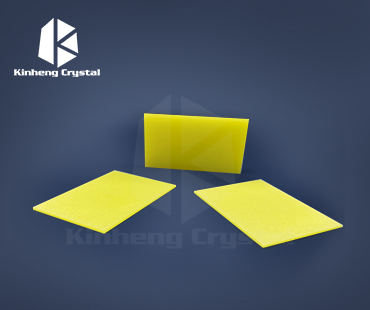

In the realm of advanced materials, Cadmium Zinc Telluride (CZT) wafers have emerged as a standout choice, particularly for applications in infrared detection and high-energy physics. The unique properties of CZT — including its excellent detector efficiency and high atomic number — make it an ideal material for various sectors, such as medical imaging, aerospace, and security. As global demand for reliable and efficient semiconductor materials continues to rise, the advantages of CZT wafers become even more pronounced. Manufacturers and suppliers of CZT wafers are increasingly focusing on quality and precision in their production processes. State-of-the-art growth techniques and cutting-edge fabrication methods ensure that each wafer meets stringent specifications, thereby enhancing performance outcomes in end-user applications. The consistent supply of high-quality CZT wafers gives procurement managers peace of mind, knowing that they are utilizing leading-edge materials that can significantly impact their projects. Furthermore, with an eye on sustainability and environmental responsibility, the production of Cadmium Zinc Telluride wafers is evolving. Efforts to minimize waste and optimize resource usage align with global trends, emphasizing the importance of choosing suppliers who prioritize sustainable practices. As the market continues to grow, global buyers seeking innovative solutions in semiconductor technology will find that CZT wafers stand out, offering unparalleled reliability and efficiency.

Cadmium Zinc Telluride Wafer Products Stands Out

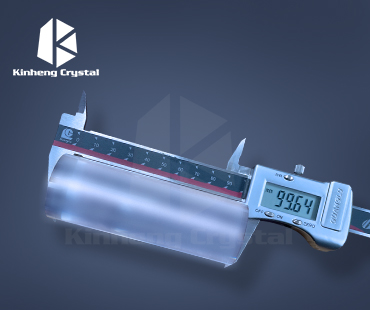

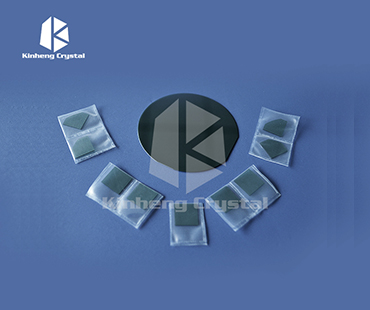

| Product Type | Diameter (mm) | Thickness (mm) | Grade | Application |

|---|---|---|---|---|

| CZT Wafer A | 50 | 0.5 | High Purity | X-ray Detectors |

| CZT Wafer B | 75 | 1.0 | Research Grade | Gamma Ray Imaging |

| CZT Wafer C | 100 | 0.7 | Standard Quality | Medical Imaging |

| CZT Wafer D | 25 | 0.3 | Ultra High Purity | Nuclear Research |

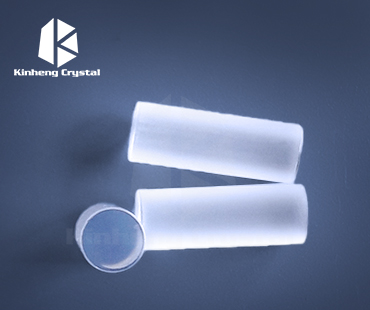

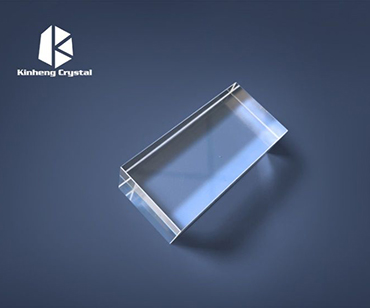

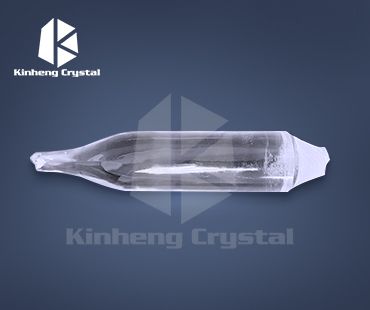

Related Products