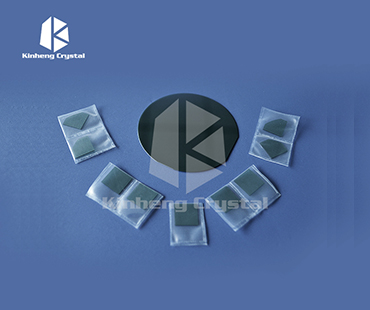

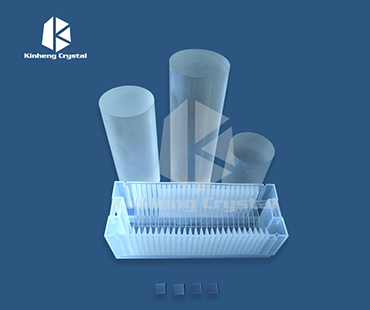

Cheap Bgo Wafer from Leading Factories - Quality You Can Trust

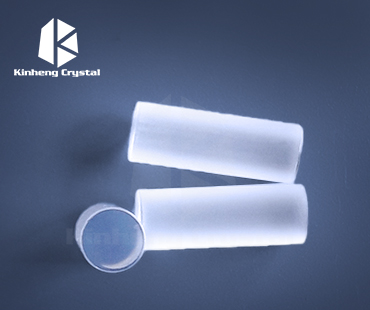

When it comes to sourcing Bgo Wafer, I understand the importance of finding quality options that won't break the bank. That’s why I’m excited to share that our Bgo Wafers are not just affordable, but also manufactured in state-of-the-art factories with strict quality controls in place. With these wafers, you're not only getting a cheap solution for your needs, but also a reliable product that enhances your offerings. Whether you’re in the confectionery business or looking to incorporate them into your manufacturing process, these wafers provide versatility and premium taste without the hefty price tag. Choosing us means aligning with a partner who values both quality and cost-efficiency. I’m here to help you make the best decision for your business, ensuring you get the most value for your investment. Let’s talk and explore how our Bgo Wafer can fit perfectly into your supply chain!

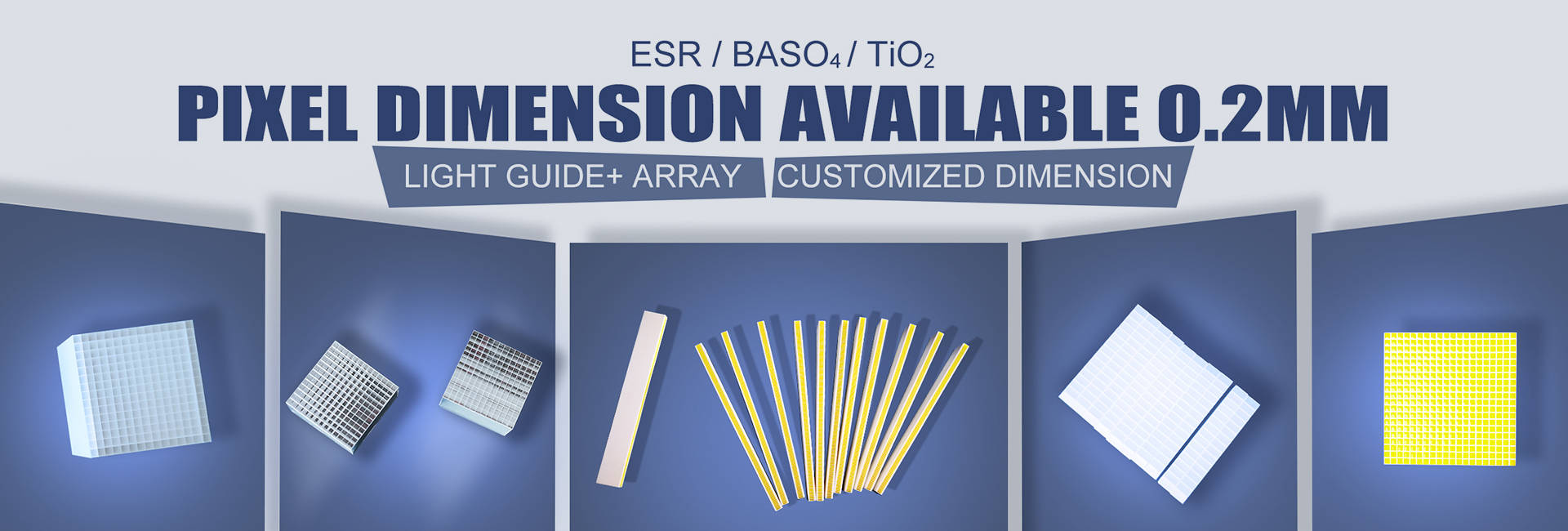

Bgo Wafer Application Service

In the rapidly evolving semiconductor industry, the demand for advanced materials continues to rise. Bgo Wafer Application Service stands out as a crucial solution for manufacturers seeking to enhance the performance and reliability of their products. This service caters to a diverse range of applications, offering customized solutions that meet the stringent requirements of today’s technological landscape. By leveraging cutting-edge techniques and rigorous quality control, Bgo Wafer Application Service ensures optimal outcomes for various sectors including telecommunications, automotive, and consumer electronics. The precision and versatility of Bgo wafers enable businesses to push the boundaries of innovation. With the ability to manipulate specific characteristics, such as thickness and surface quality, manufacturers can achieve significant improvements in yield and functionality. This flexibility is especially beneficial in high-stakes applications where performance is critical. By engaging with Bgo Wafer Application Service, global buyers can gain unparalleled access to tailored support, ensuring that their projects not only meet but exceed industry standards. Moreover, the integration of sustainability into wafer production processes enhances the attractiveness of this service. With a growing emphasis on environmentally friendly practices, choosing Bgo Wafer Application Service signifies a commitment to responsible sourcing and innovation. As international markets seek reliable partners to navigate the complexities of modern manufacturing, this service represents a strategic advantage for those looking to remain competitive in an increasingly interconnected world.

Bgo Wafer Application Service

| Service Type | Description | Applications | Material Type | Technology Used |

|---|---|---|---|---|

| Wafer Slicing | Precision cutting of semiconductor wafers | Electronics, Solar Panels | Silicon, GaN | Laser Cutting Technology |

| Wafer Polishing | Surface smoothing for enhanced performance | Electronics, Sensors | Silicon, Sapphire | Chemical Mechanical Polishing (CMP) |

| Wafer Dicing | Dicing wafers into individual chips | Semiconductor Manufacturing | Silicon, Compound Semiconductors | Diamond Blade Cutting |

| Wafer Bonding | Joining multiple wafers for integrated circuits | MEMS, 3D ICs | Silicon, Glass | Anodic Bonding |

| Wafer Cleaning | Removing contaminants and particles | Manufacturing Processes | Silicon, Silicon Carbide | Ultrasonic Cleaning |

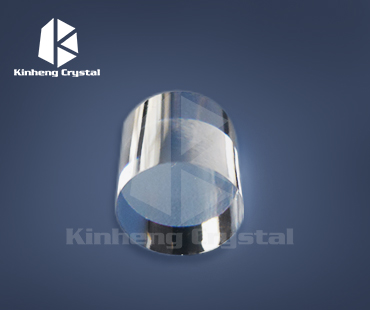

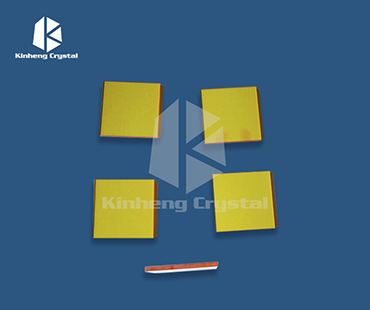

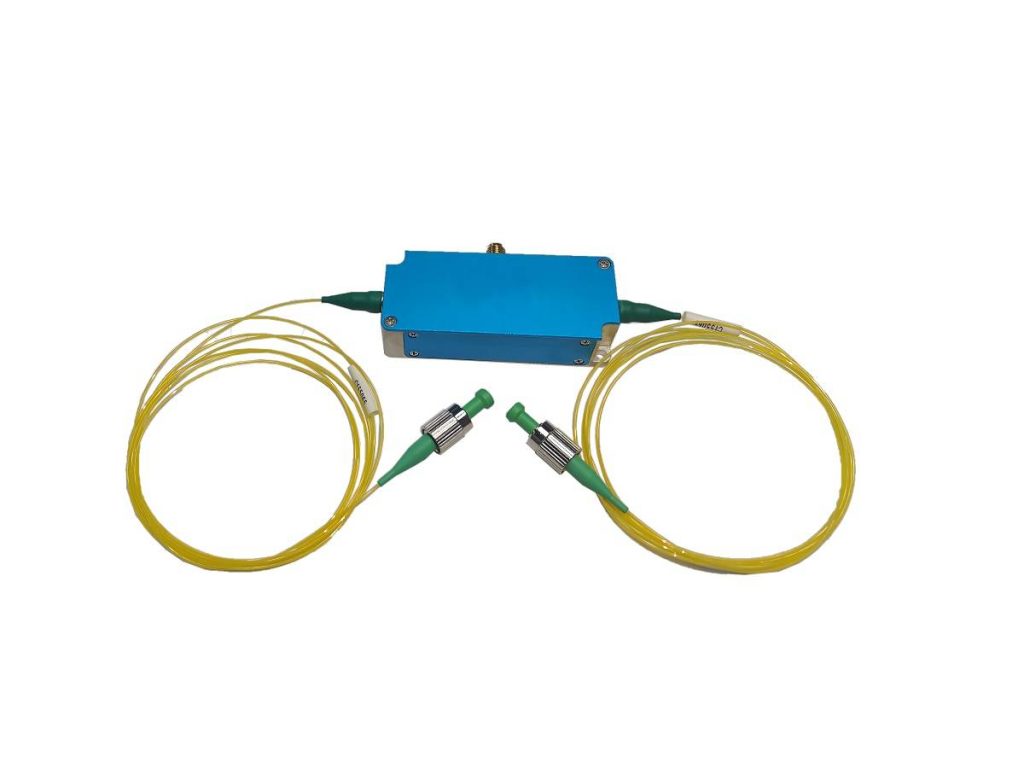

Related Products