Custom Bi4Ge3O12 Wafer Suppliers for High-Quality Semiconductor Materials

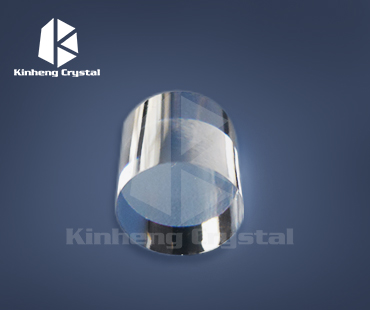

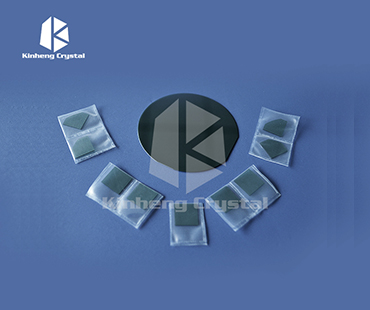

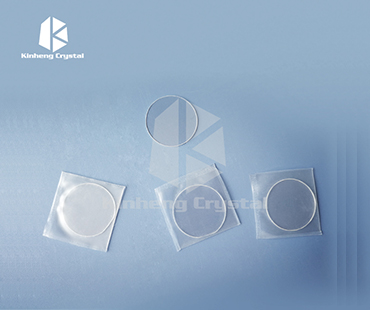

As a professional in the semiconductor industry, I understand the challenges of sourcing high-quality materials. That’s why I’m excited to offer Bi4Ge3O12 wafers, perfect for your custom applications. These wafers are known for their exceptional optical and piezoelectric properties, making them ideal for advanced electronic devices and sensors. When choosing suppliers for critical components like these, reliability is key. I take pride in ensuring that our Bi4Ge3O12 wafers meet rigorous quality standards, providing you with the consistency and performance you need. Whether you're developing cutting-edge technologies or enhancing existing products, you can count on us for tailored solutions that fit your specific requirements. Feel free to reach out if you need samples or more information about our sourcing capabilities. Together, we can elevate your projects with the right materials!

Bi4Ge3O12 Wafer Ahead of the Curve Supplies the World\u2019s Top Brands

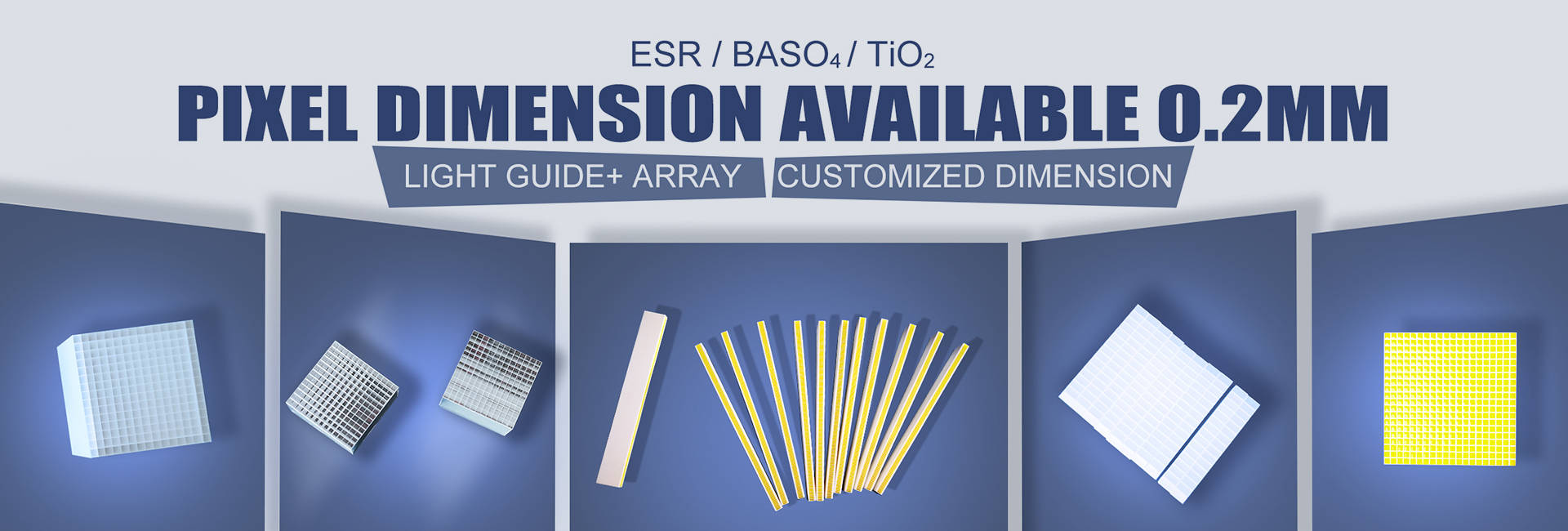

In today’s fast-evolving technology landscape, industries are increasingly reliant on high-quality materials to drive innovation and meet demanding specifications. Among these, Bi4Ge3O12 wafers stand out for their unique properties, which enable superior performance in optical and electronic applications. These wafers are engineered to provide exceptional stability, transparency, and a high refractive index, making them ideal for use in advanced devices and systems across various sectors, including telecommunications, aerospace, and consumer electronics. As a key player in the supply of Bi4Ge3O12 wafers, our commitment to precision craftsmanship ensures that our products meet the highest industry standards. We focus on maintaining rigorous quality control processes throughout manufacturing, guaranteeing that our wafers deliver not only in performance but also in reliability. Our clients, ranging from emerging startups to established global brands, recognize the value of our materials in enhancing their technological capabilities and achieving competitive advantages in their respective markets. The demand for high-performance materials continues to rise, driven by the pursuit of miniaturization and greater efficiency in devices. By aligning with leading brands worldwide, we are positioned to contribute to breakthrough advancements and sustainable solutions. With a keen focus on innovation and customer satisfaction, we invite global procurement professionals to explore the potential of Bi4Ge3O12 wafers and integrate them into their product lines for enhanced performance and future-ready solutions.

Bi4Ge3O12 Wafer Ahead of the Curve Supplies the World’s Top Brands

| Parameter | Value | Unit |

|---|---|---|

| Thickness | 0.5 | mm |

| Diameter | 200 | mm |

| Purity | 99.99 | % |

| Thermal Conductivity | 1.5 | W/mK |

| Band Gap | 2.5 | eV |

Related Products