Premium Single Crystal Substrates from Leading China Manufacturer

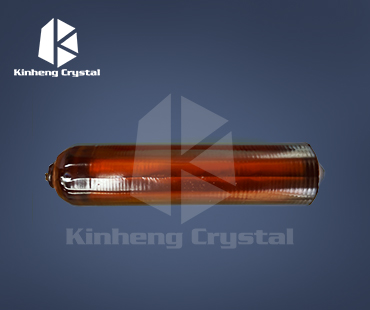

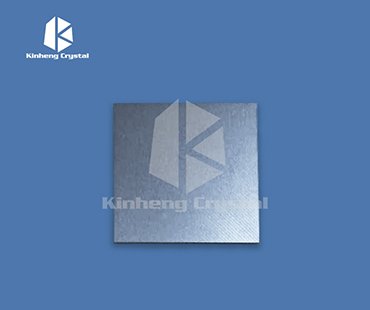

When I decided to Buy Single Crystal Substrates, I wanted only the best quality for my applications. Sourcing these substrates from a reliable manufacturer in China makes a significant difference in performance and durability. The precise lattice structure and high purity of these crystals enhance the efficiency of various advanced technologies, including semiconductor devices and optics. I appreciate the strict manufacturing processes and quality control that Chinese manufacturers implement, ensuring each substrate meets rigorous standards. Whether I need large quantities for production or specific sizes for research, these manufacturers provide customization to fit my needs. Plus, their competitive pricing helps me manage costs effectively while not compromising on quality. For anyone in the electronics or materials science fields, investing in single crystal substrates from trusted Chinese sources is a game changer. The enhanced performance and reliability I’ve experienced have truly elevated my projects.

Buy Single Crystal Substrates Manufacturer Ahead of the Curve

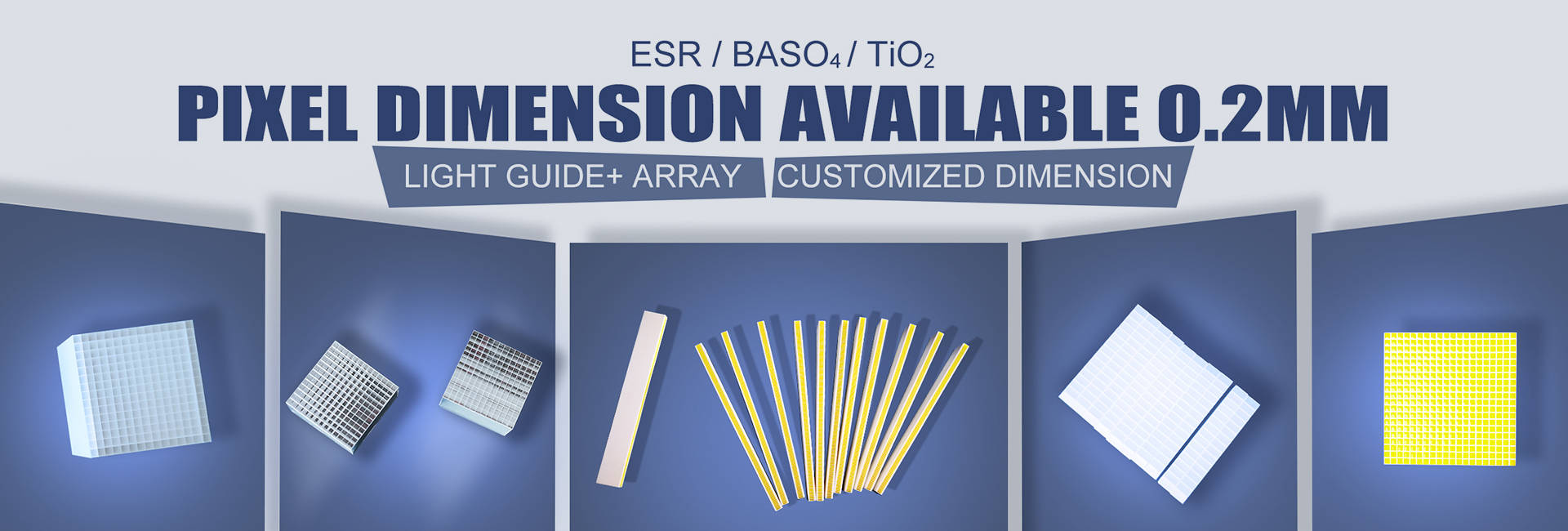

In the dynamic world of crystal materials, the demand for single crystal substrates continues to soar, driven by advancements in technology and the growing applications in fields such as electronics, photonics, and quantum computing. Choosing the right manufacturer is crucial for procurement professionals looking to stay ahead of the curve. A reputable supplier not only guarantees high-quality substrates but also ensures consistent supply and innovation in product development. Single crystal substrates offer unparalleled quality and performance, making them essential in the fabrication of high-efficiency devices. They provide superior structural integrity and minimal defects compared to their polycrystalline counterparts. By investing in these substrates from a forward-thinking manufacturer, businesses can enhance their product capabilities, reduce production costs, and improve yield rates. As the global market evolves, aligning with a manufacturer that prioritizes research and development will provide businesses with a competitive edge. A proactive supplier recognizes emerging trends and adapts their offerings to meet the evolving needs of their customers. Therefore, by sourcing single crystal substrates from a cutting-edge manufacturer, companies position themselves for success in an increasingly competitive landscape.

Buy Single Crystal Substrates Manufacturer Ahead of the Curve

| Material Type | Crystal Orientation | Thickness (mm) | Size (mm) | Application |

|---|---|---|---|---|

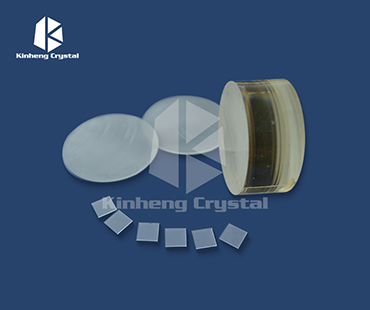

| Silicon (Si) | (100) | 0.5 | 100 x 100 | Electronics |

| Gallium Nitride (GaN) | (0001) | 0.75 | 50 x 50 | LEDs |

| Sapphire (Al2O3) | (0001) | 0.5 | 25 x 25 | Optoelectronics |

| Silicon Carbide (SiC) | (0001) | 1.0 | 150 x 150 | Power Devices |

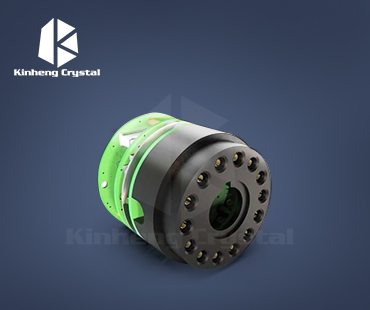

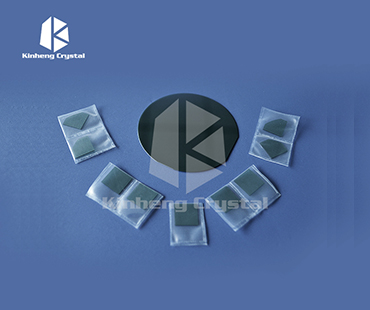

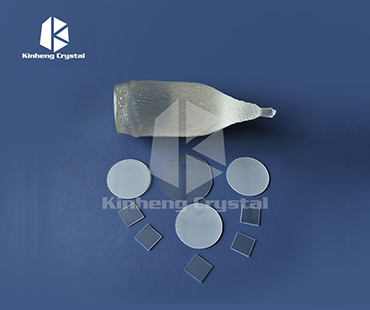

Related Products