High-Quality Custom Single Crystal Substrates from Trusted Supplier

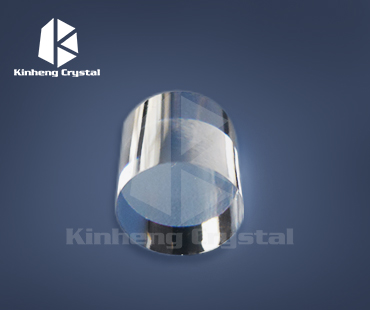

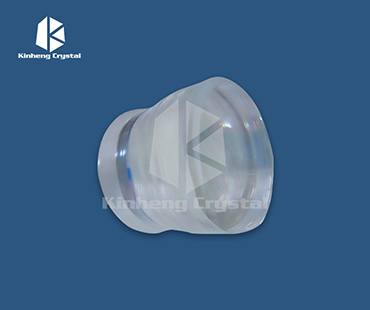

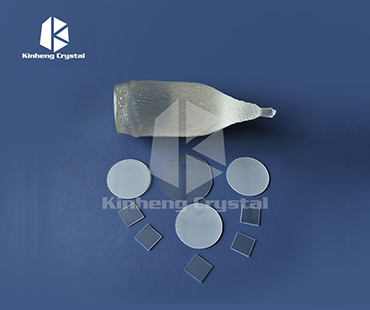

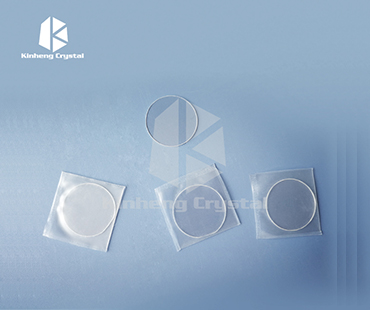

When you're in the market for custom single crystal substrates, quality is non-negotiable. I understand that as a B2B purchaser, you seek high-quality products that meet your precise specifications. That's why I am excited to offer you a range of premium custom single crystal substrates designed to enhance your applications. Our substrates are crafted with meticulous attention to detail, ensuring superior performance and durability. As a reliable supplier, I prioritize your needs and provide tailored solutions that fit your project requirements. Whether you're working on advanced research, semiconductor fabrication, or precision optics, our substrates deliver exceptional results. With years of experience in the industry, I'm committed to maintaining the highest standards in product quality and customer service. Let's work together to fulfill your crystal substrate needs—reach out today, and experience the difference that high-quality materials can make in your projects!

Custom Single Crystal Substrates For the Current Year Sets the Industry Standard

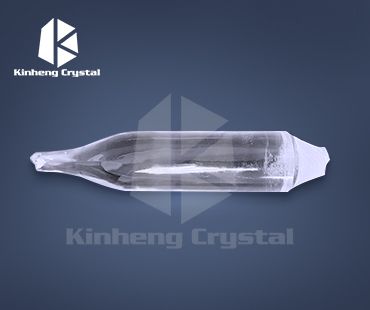

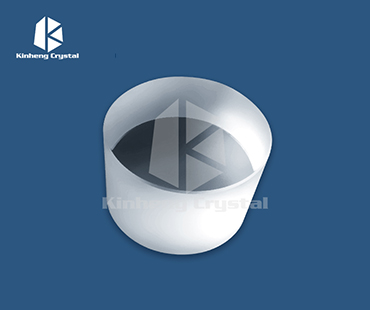

In the fast-evolving world of semiconductor manufacturing and advanced optics, the demand for custom single crystal substrates has reached new heights this year. As industries worldwide strive for precision and performance, these substrates have emerged as a critical component in various applications, from electronics to photonics. The ability to tailor the specifications of single crystal substrates not only meets the diverse needs of global buyers but also sets the industry standard for quality and reliability. Custom single crystal substrates are engineered to enhance the performance of electronic devices and optical components. With advancements in crystal growth technology, manufacturers can now produce substrates that are not only defect-free but also exhibit superior thermal and mechanical properties. This is particularly beneficial for high-end applications, where material integrity directly impacts functionality and longevity. The customization options allow procurement professionals to specify dimensions, orientations, and surface finishes that align perfectly with their project requirements, fostering innovation and efficiency in product development. As global supply chains adapt to challenges and opportunities, securing a reliable source of high-quality custom single crystal substrates has become paramount. Companies seeking to maintain a competitive edge should prioritize partnerships with suppliers who demonstrate a commitment to excellence and innovation. Investing in state-of-the-art materials now positions businesses at the forefront of their industries, ready to meet the complex demands of the future with confidence and precision.

Custom Single Crystal Substrates For the Current Year Sets the Industry Standard

| Substrate Type | Dimensions (mm) | Orientation | Material | Applications | Remarks |

|---|---|---|---|---|---|

| Silicon | 100 x 100 | (100) | Si | Microelectronics | High purity |

| Sapphire | 150 x 150 | (0001) | Al2O3 | LEDs, Sensors | Good thermal conductivity |

| Gallium Nitride | 200 x 200 | (0001) | GaN | Optoelectronics | High electron mobility |

| Silicon Carbide | 100 x 100 | (0001) | SiC | Power Electronics | High thermal stability |

| Lithium Niobate | 50 x 50 | (100) | LiNbO3 | Optical Devices | Non-linear optical properties |

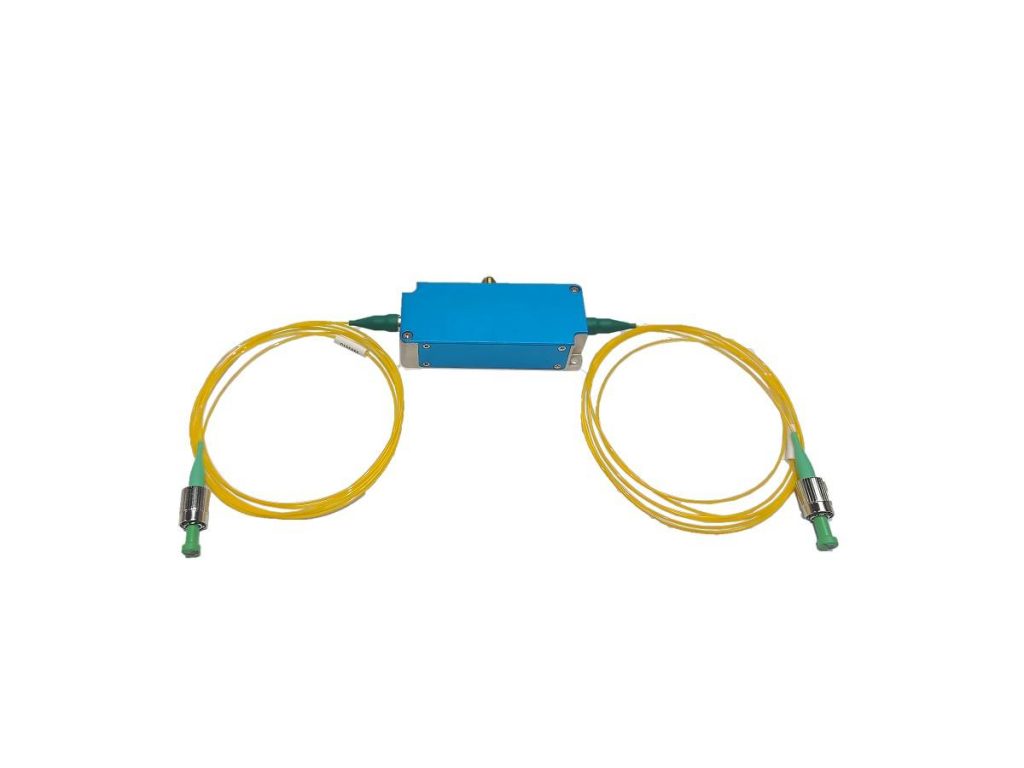

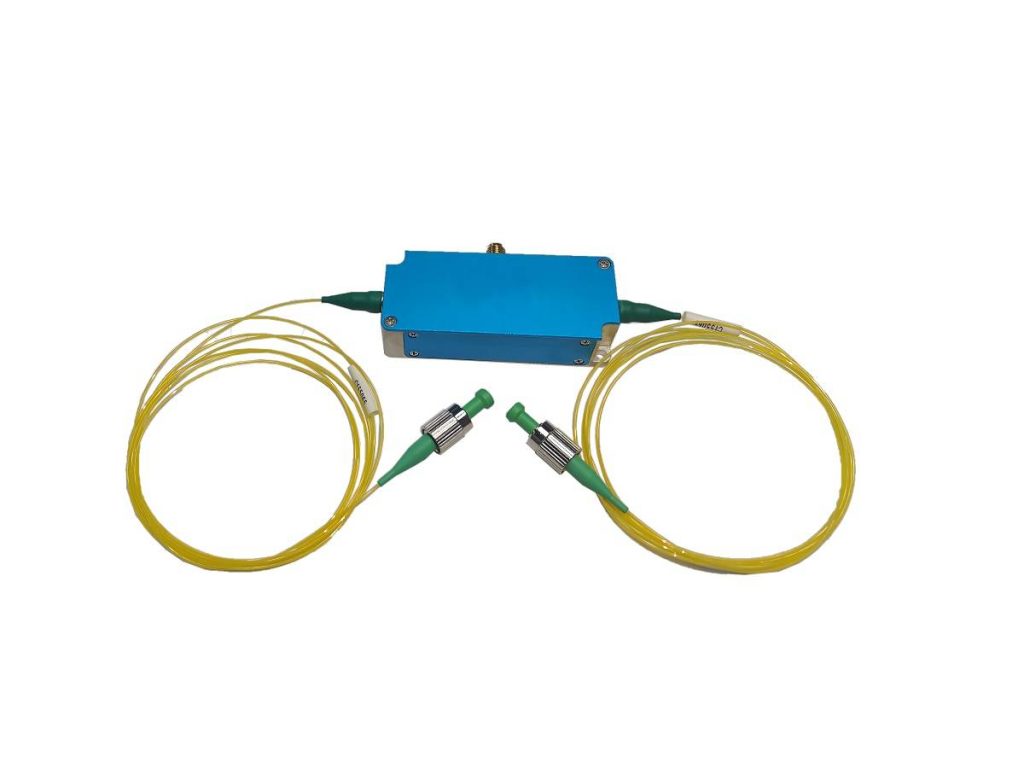

Related Products