Custom Forged Scintillator Suppliers for Your Unique Needs

As a buyer in the specialized field of scintillator technology, I often seek high-quality options that truly meet my needs. That's where forged scintillators come into play. These products deliver unmatched performance, enhancing both the precision and reliability of detection processes across various applications. When exploring suppliers, I appreciate those who offer custom solutions tailored to specific project requirements. With the ability to adapt to different dimensions and characteristics, forged scintillators can significantly improve efficiency in my operations. It’s essential for me to partner with suppliers who not only understand the technical nuances but also prioritize customer service and support. Ensuring that my projects run smoothly is crucial, and the right forged scintillator can make all the difference. Collaborating with knowledgeable suppliers empowers me to make informed decisions, enhancing our collective success in this competitive market.

Forged Scintillator Winning in 2025 Manufacturers You Can Rely On

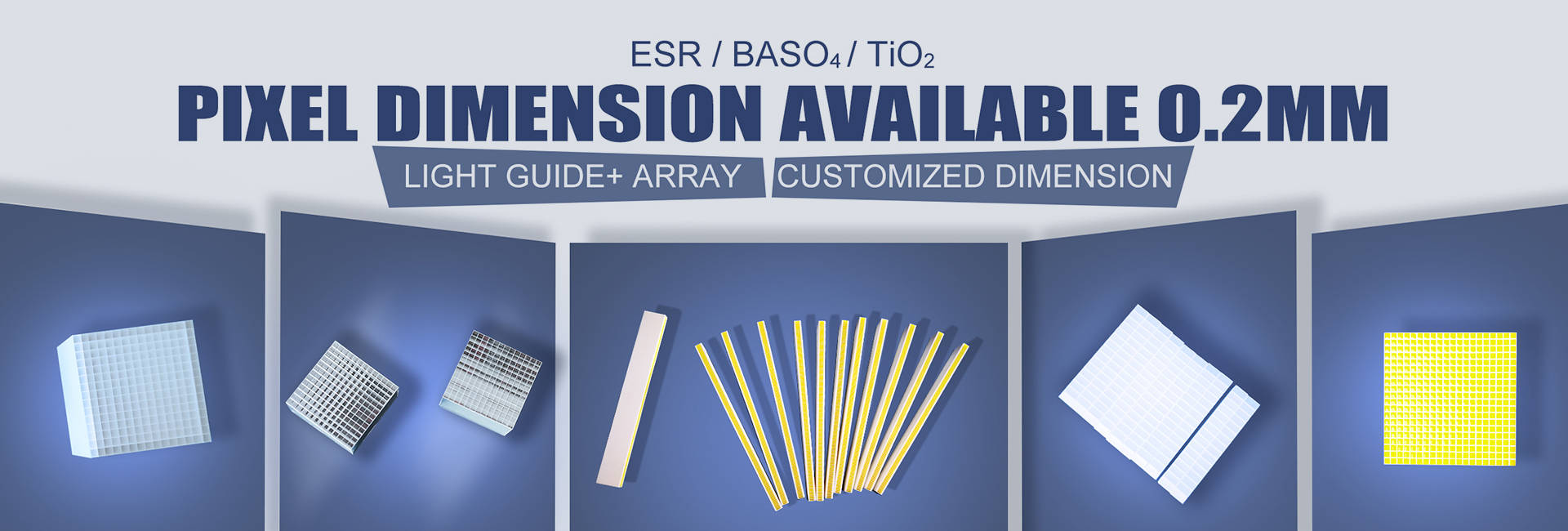

As the demand for high-performance scintillation materials continues to rise in various applications, from medical imaging to radiation detection, manufacturers are adapting to meet these challenges. The emergence of forged scintillators, known for their superior efficiency and durability, positions them as a leading choice for businesses globally. These advanced materials not only enhance detection capabilities but also ensure longevity in demanding environments. As we approach 2025, it's crucial for procurement teams to partner with manufacturers who prioritize quality and innovation. In selecting reliable suppliers, one should consider factors such as production techniques, material purity, and customization options. The best manufacturers leverage cutting-edge technology and raw materials, ensuring their scintillators exceed industry standards. Furthermore, collaboration between manufacturers and customers can lead to tailored solutions that meet specific project requirements, boosting overall effectiveness and performance. Looking toward the future, the integration of sustainable practices and the continual refinement of product offerings will be key. Procurement professionals are encouraged to forge partnerships with forward-thinking manufacturers that not only deliver exceptional products but are also committed to environmental responsibility. By aligning with such companies, buyers can secure a dependable supply of forged scintillators, enabling them to remain competitive in an ever-evolving market landscape.

Forged Scintillator Winning in 2025 Manufacturers You Can Rely On

| Manufacturer Code | Scintillator Type | Key Features | Application Areas | Reliability Rating |

|---|---|---|---|---|

| FS-1001 | Calcium Fluoride | High light output, fast response | Medical Imaging, Security | 4.8/5 |

| FS-1002 | Sodium Iodide | Excellent energy resolution | Nuclear Medicine, Research | 4.7/5 |

| FS-1003 | Bismuth Germanate | High density, good stability | High-energy Physics, Radiation Therapy | 4.6/5 |

| FS-1004 | Organic Scintillator | Compact, versatile | Environmental Monitoring, Homeland Security | 4.5/5 |

| FS-1005 | Plastic Scintillator | Lightweight, cost-effective | Particle Detectors, Time-of-Flight Systems | 4.4/5 |

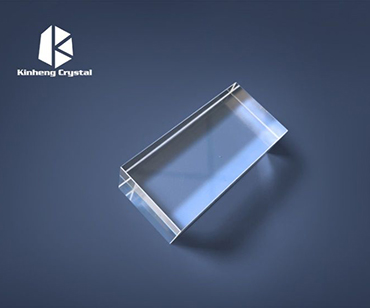

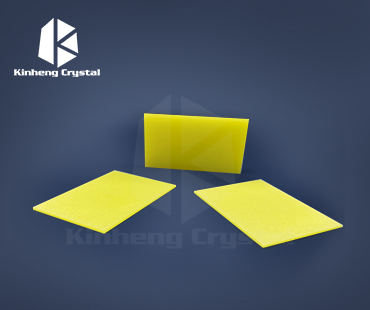

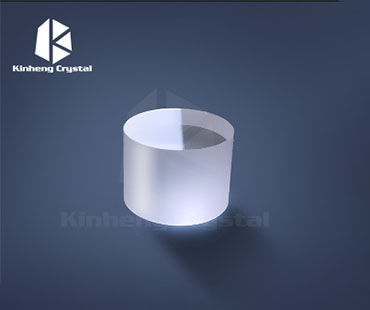

Related Products