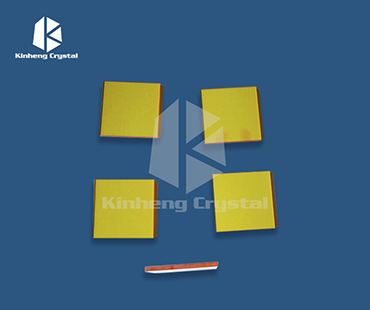

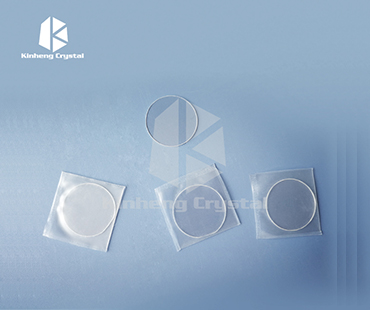

Bismuth Germanate Crystal Substrates from Leading Manufacturer in China

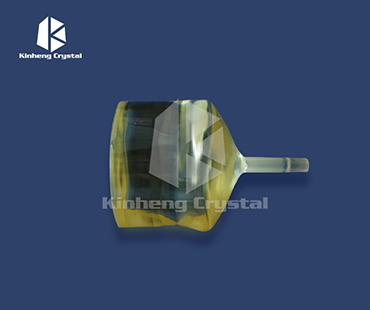

Bismuth Germanate Crystal Substrates are an essential component for advanced applications in the semiconductor and optical industries. As a manufacturer based in China, we take pride in supplying high-quality substrates that ensure optimal performance for your projects. Our Bismuth Germanate crystals are designed to provide excellent thermal stability and superior optical characteristics, making them perfect for a range of applications, including detectors and scintillation materials. We understand that every business has unique needs, so we can customize our offerings to meet your specific requirements. Our commitment to quality and precision sets us apart in the market. Partnering with us means gaining access to a reliable and experienced supplier. Ready to elevate your processes with our premium Bismuth Germanate Crystal Substrates? Let’s connect and explore how we can support your business goals with our top-notch products. Your success is our priority!

Bismuth Germanate Crystal Substrates Industry Giant Sets the Industry Standard

In recent years, the Bismuth Germanate Crystal Substrates industry has witnessed significant advancements, setting new benchmarks for quality and performance. As the demand for high-purity crystal substrates continues to rise, industry leaders are pushing the envelope to deliver superior products that meet the rigorous requirements of various applications, including optoelectronics, photonics, and advanced semiconductor technologies. The introduction of cutting-edge production techniques and quality assurance processes has enabled manufacturers to achieve unparalleled levels of crystal homogeneity and defect reduction, ensuring that end-users receive reliable and high-performing substrates. Moreover, the global marketplace is evolving, with procurement strategies becoming increasingly sophisticated. Buyers are not only looking for suppliers with competitive pricing but are also prioritizing those who demonstrate a commitment to sustainability and innovation. The ability to provide comprehensive support, from technical guidance to just-in-time delivery, is vital for companies that wish to maintain a competitive edge. As the industry continues to grow, establishing strong partnerships and fostering collaborative relationships will be crucial for success. With the emergence of advanced applications in areas such as quantum computing and high-energy physics, the role of Bismuth Germanate Crystal Substrates is poised to expand further. As procurement professionals scour the globe for the best sources, the emphasis will increasingly be on quality, reliability, and source transparency. Adopting best practices and focusing on R&D will empower suppliers to not only meet current market needs but also anticipate future trends. This proactive approach will ultimately solidify their position as leaders in a dynamic and competitive landscape.

Bismuth Germanate Crystal Substrates Industry Standards

| Property | Value | Measurement Unit |

|---|---|---|

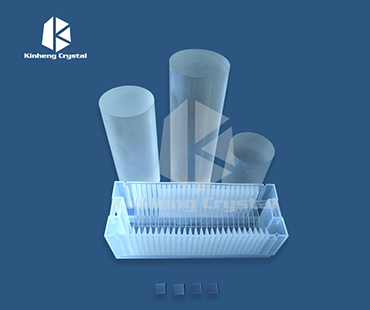

| Crystal Growth Technique | Czochralski Method | N/A |

| Typical Thickness | 1.0 - 5.0 | mm |

| Purity Level | 99.99% | % (wt) |

| Density | 9.78 | g/cm³ |

| Band Gap Energy | 2.5 | eV |

| Thermal Conductivity | 3.2 | W/m·K |

| Applications | Medical Imaging, Radiation Detection | N/A |

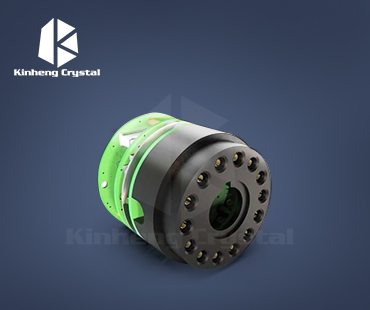

Related Products