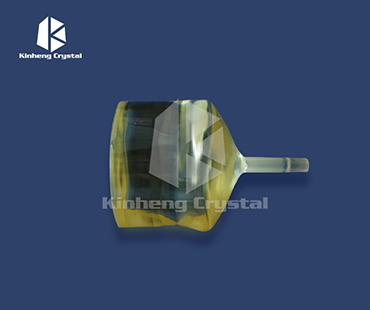

Custom GGG Substrate from Top Suppliers for Your Project Needs

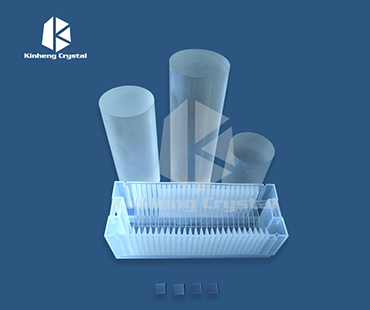

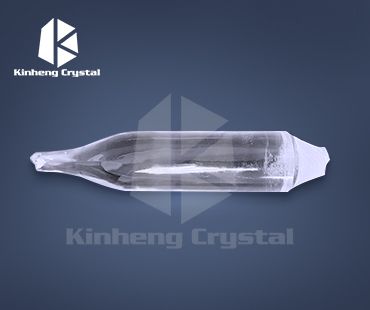

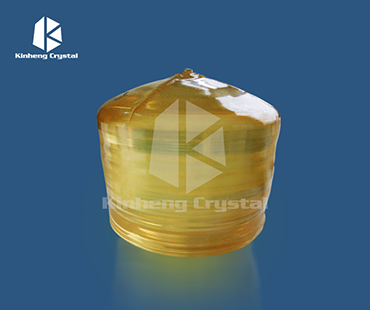

When it comes to high-quality GGG Substrate, I’ve found that not all products are created equal. As a B2B purchaser, you want reliable suppliers who understand your specific needs. That’s where custom solutions come into play. With GGG Substrate, I appreciate the versatility it offers, making it perfect for various applications in your industry. It’s durable and designed to withstand harsh conditions, which means fewer replacements and long-term savings. Working with the right suppliers is crucial, and I can assure you that partnering with us ensures you get not only the best GGG Substrate but also excellent customer service. I know how important it is to have a responsive team that can tailor materials to your specifications. Don’t settle for generic options—let’s talk about how our custom offerings can elevate your projects to the next level. Your satisfaction is our priority, and we’re here to support your business every step of the way.

GGG Substrate Supplier For the Current Year

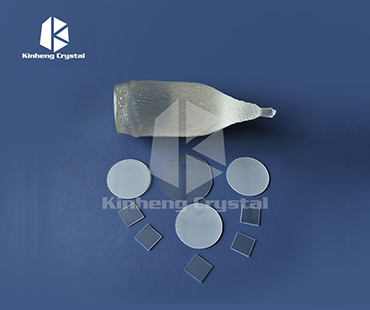

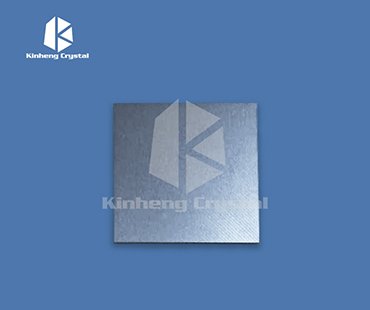

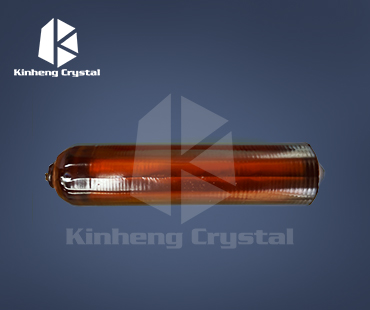

As the demand for GGG substrates continues to grow in various applications, sourcing the right supplier is crucial for businesses worldwide. GGG, or Gallium Garnet, is renowned for its excellent thermal and optical properties, making it a preferred choice in industries such as telecommunications, electronics, and photonics. Companies looking to stay ahead in their respective fields must consider factors such as material quality, supplier reliability, and pricing structures to ensure optimal results. In the current year, it is essential for global purchasers to align with suppliers that not only provide high-quality GGG substrates but also understand the specific requirements of different applications. With an increasing emphasis on innovation and performance, choosing a supplier that can offer tailored solutions, timely deliveries, and responsive customer support is vital. Establishing a partnership with a reputable supplier will empower businesses to enhance their product offerings while meeting market demands. Furthermore, the integration of advanced manufacturing technologies and robust quality control measures is key to maintaining the integrity and functionality of GGG substrates. Buyers should actively seek suppliers that prioritize transparency in their production processes and possess certifications that validate their commitment to quality. By doing so, businesses can confidently incorporate GGG substrates into their projects, ensuring that they remain competitive in an ever-evolving market.

GGG Substrate Supplier For the Current Year

| Supplier Name | Location | Product Type | Material | Application | Rating |

|---|---|---|---|---|---|

| Supplier A | USA | Substrate | Ceramic | Electronics | 4.5 |

| Supplier B | Germany | Substrate | Silicon | Photovoltaic | 4.7 |

| Supplier C | Japan | Substrate | Gallium Nitride | LEDs | 4.6 |

| Supplier D | South Korea | Substrate | Glass | Display | 4.8 |

| Supplier E | China | Substrate | Alumina | RFID | 4.4 |

Related Products