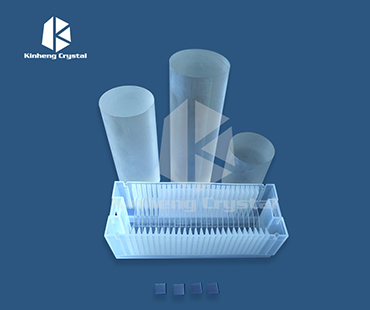

Wholesale LaAlO3 Lanthanum Aluminate Crystal Substrates Manufacturers

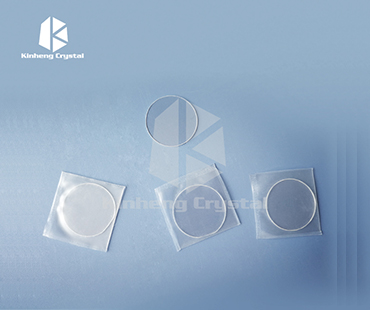

When I think about top-quality substrates for advanced applications, LaAlO3 Lanthanum Aluminate Crystal Substrates come to mind. These substrates are essential for various high-tech processes, thanks to their excellent lattice match properties. I often recommend them to manufacturers seeking reliable materials for electronics, photonics, and various research applications. As someone who understands the B2B landscape, I know that sourcing these crystal substrates wholesale can significantly lower costs without sacrificing quality. Their stability and versatility make them an ideal choice for manufacturers looking to enhance product performance. If you're considering options, I can assure you that LaAlO3 substrates not only meet but exceed industry standards. It’s an investment that truly pays off in the long run, allowing seamless integration into your projects. Let’s elevate your manufacturing capabilities with these top-notch crystals!

LaAlO3 Lanthanum Aluminate Crystal Substrates Guarantees Peak Performance Supplies the World\u2019s Top Brands

LaAlO3, or lanthanum aluminate, has emerged as a crucial material in the production of high-quality crystal substrates. This material is known for its excellent lattice matching with a variety of functional materials, making it a preferred choice in advanced applications such as semiconductor manufacturing, optoelectronics, and photonics. The unique properties of LaAlO3, including its wide bandgap, high thermal stability, and low defect density, ensure that it delivers optimal performance for the cutting-edge technologies of top brands worldwide. For global buyers seeking reliability and performance, investing in LaAlO3 crystal substrates means gaining access to materials that significantly enhance the efficiency and efficacy of their end products. These substrates not only allow for improved surface quality and uniformity, but they also support the growth of high-quality thin films that are essential for various applications, ranging from energy-efficient devices to next-generation quantum computing solutions. By selecting LaAlO3, procurement professionals can ensure their production processes remain at the forefront of innovation. The demand for premium materials like LaAlO3 continues to rise as industries evolve and strive for higher performance standards. By partnering with key suppliers who specialize in advanced crystal materials, businesses can secure a competitive advantage in the marketplace. As manufacturers focus on delivering unparalleled quality and performance, the reliable incorporation of lanthanum aluminate substrates will play an instrumental role in shaping the technologies of tomorrow.

LaAlO3 Lanthanum Aluminate Crystal Substrates Performance Data

| Property | Value | Unit |

|---|---|---|

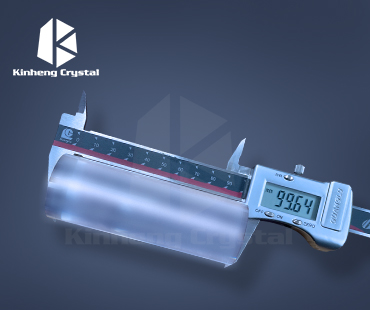

| Lattice Constant | 3.87 | Å |

| Dielectric Constant | 24 | - |

| Thermal Conductivity | 25 | W/m·K |

| Bandgap Energy | 5.6 | eV |

| Refractive Index | 1.8 | - |

| Growth Method | Molecular Beam Epitaxy | - |

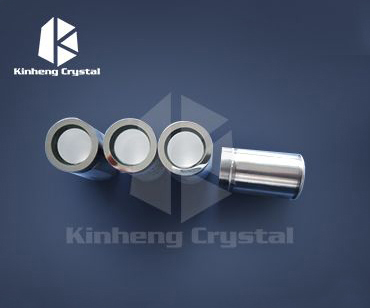

Related Products