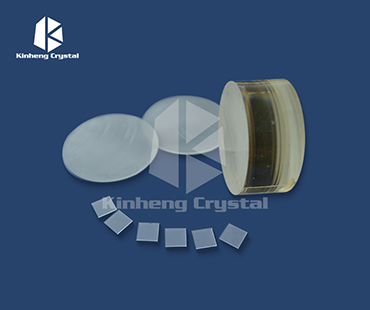

High-Quality LiNbO3 Wafers with CE Certification from Trusted Factory

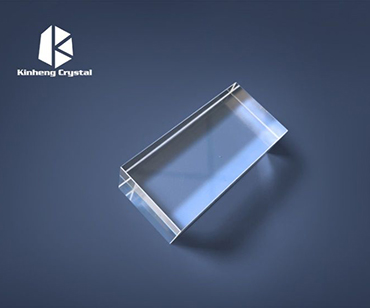

As a trusted supplier of LiNbO3 wafers, I understand the critical importance of quality and compliance in your projects. Our wafers are not just high-performance; they come with CE Certification, ensuring they meet stringent European safety and environmental standards. This certification gives you peace of mind that you’re investing in a reliable product that complies with market regulations. Having worked in the industry for years, I've witnessed the challenges faced by manufacturers in sourcing reliable materials. That’s why I prioritize transparency and consistency in our production process. Our factory employs state-of-the-art technology to produce LiNbO3 wafers that meet your exact specifications. Collaborating with us means you’re not only getting exceptional product quality but also the assurance of a partnership built on trust and expertise. Let’s discuss how our LiNbO3 wafers can meet your specific needs and drive your success.

LiNbO3 Wafers Exceeds Industry Benchmarks More Than a Supplier - A Partner

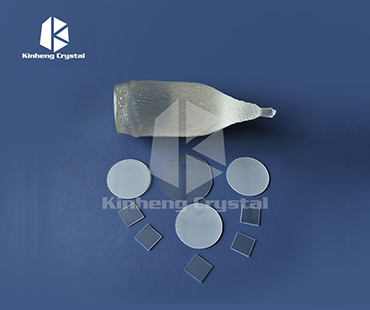

In the rapidly evolving landscape of advanced materials, the demand for high-quality lithium niobate (LiNbO3) wafers is on the rise. As industries ranging from telecommunications to photonics push the boundaries of technology, the need for reliable partners who can deliver exceptional quality and performance has never been greater. Meeting and exceeding industry benchmarks is not just a goal; it is a commitment to innovation, precision, and excellence that defines top-tier manufacturers in this field. Suppliers that merely meet basic requirements often fall short in the competitive global market. In contrast, the true value lies in creating vibrant partnerships that emphasize collaboration, insight sharing, and mutual growth. Companies that invest in understanding their clients’ unique challenges and objectives, while providing tailored solutions and technical support, position themselves as indispensable allies. This results in enhanced operational efficiency and innovative breakthroughs, ultimately driving success across industries. As global procurement professionals seek out dependable sources for LiNbO3 wafers, the emphasis should be on selecting partners who not only provide superior products but also foster long-term relationships. Those who understand the intricacies of various applications, from optical devices to high-frequency electronics, can offer significant advantages. The future of material science lies in partnerships that innovate together, aiming higher than standard expectations and unlocking unprecedented possibilities in technology development.

LiNbO3 Wafers Exceeds Industry Benchmarks More Than a Supplier - A Partner

| Parameter | Benchmark Value | Our Value | Notes |

|---|---|---|---|

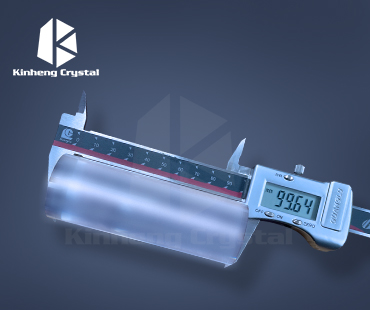

| Thickness | 500 µm | 490 µm | Optimized for performance |

| Diameter | 2 inch | 2 inch | Standard size maintained |

| Homogeneity | < 0.5% | < 0.3% | Superior quality control |

| Optical Loss | < 0.3 dB/cm | < 0.2 dB/cm | Enhanced light transmission |

| Processing Time | 14 days | 10 days | Faster turnaround |

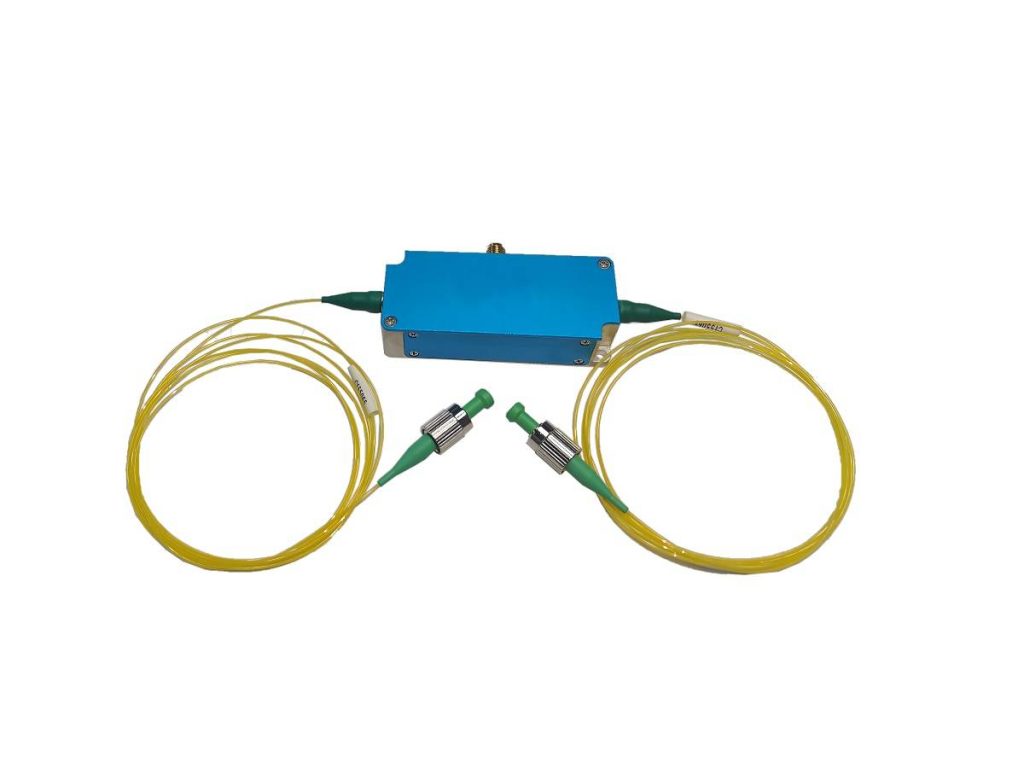

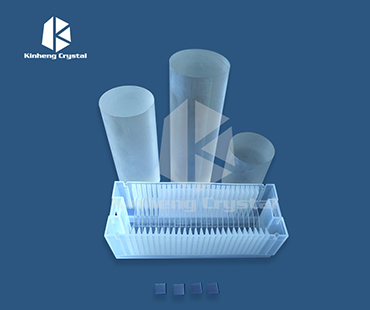

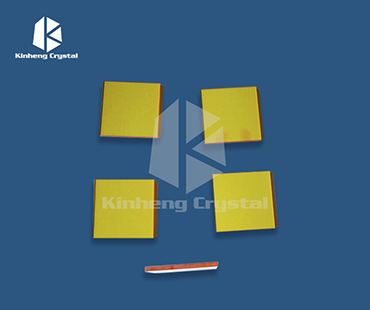

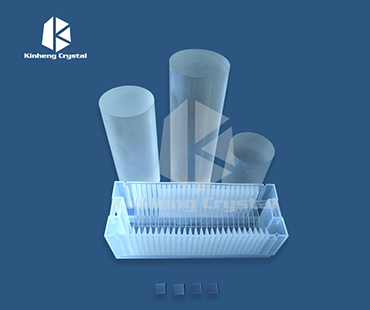

Related Products