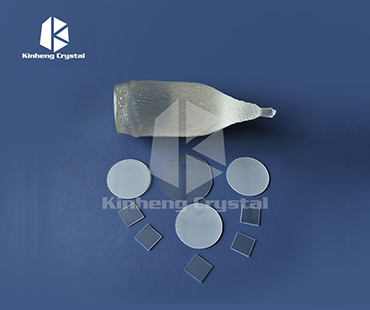

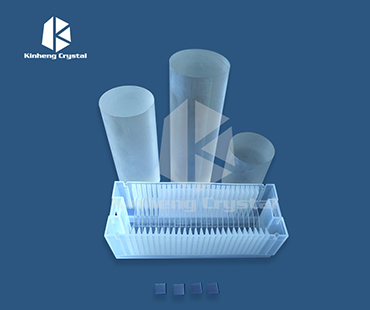

Custom Luag Ce Wafer Suppliers for Quality Solutions

When it comes to sourcing high-quality Luag Ce Wafer, I understand how crucial it is to find reliable suppliers. As a buyer, you want products that not only meet your specifications but also exceed your expectations in terms of performance and durability. That's where our custom options come in. We specialize in providing tailor-made Luag Ce Wafers that align perfectly with your project needs. Our team works closely with various industries, ensuring that each wafer is crafted to your exact requirements. Whether you're in electronics, manufacturing, or another sector, our solutions are designed to give you the competitive edge you need. With an emphasis on quality and precision, we guarantee that our Luag Ce Wafers will deliver optimal results. Let me help you streamline your sourcing process and bring your projects to fruition with the perfect wafers from trusted suppliers. Reach out to learn more about our custom offerings!

Luag Ce Wafer Sets the Industry Standard Factory-Direct Excellence

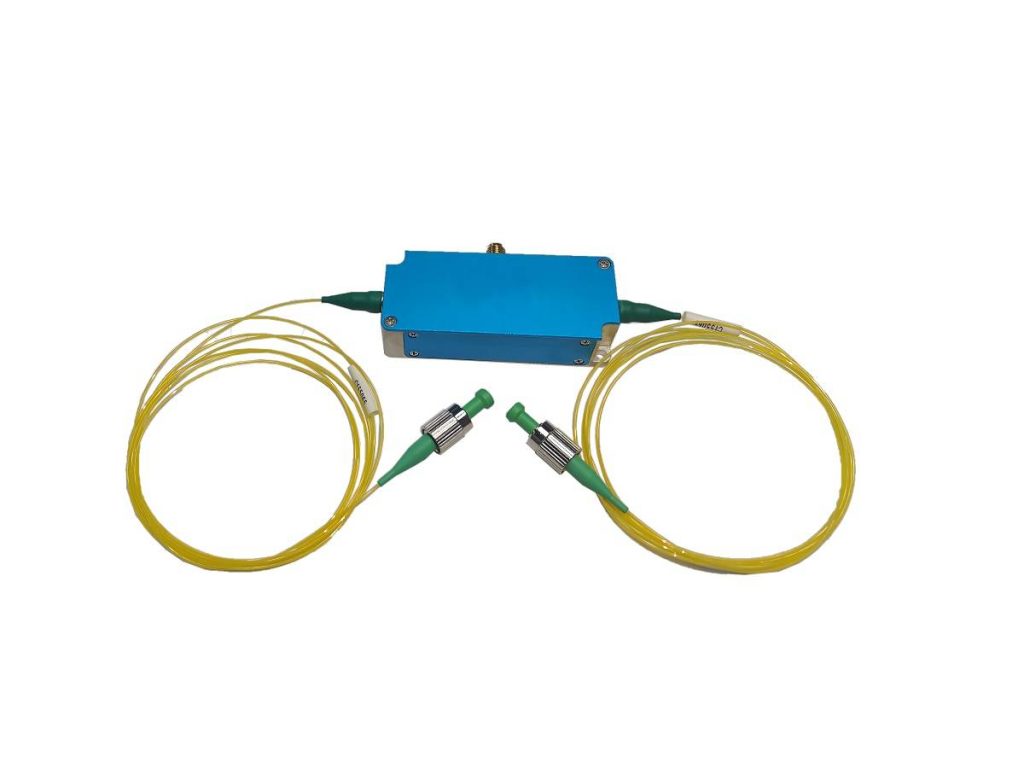

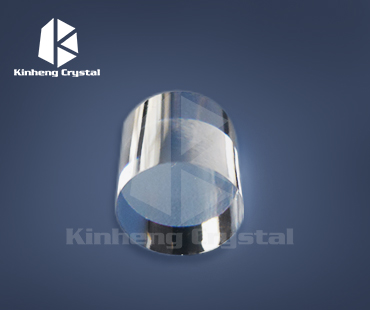

In today's fast-paced technology landscape, the demand for high-quality components is ever-increasing. The introduction of Luag Ce Wafer Sets has set a new benchmark in the industry, showcasing unrivaled factory-direct excellence. These wafers are engineered to meet the rigorous standards of various applications, from semiconductor manufacturing to advanced optical systems. With a focus on precision and quality, they ensure optimal performance and reliability in critical processes. Designed with cutting-edge technologies, Luag Ce Wafer Sets not only enhance efficiency but also reduce waste and costs, making them an invaluable asset for global procurement professionals. The direct factory-to-customer approach eliminates unnecessary intermediaries, enabling buyers to benefit from competitive pricing without compromising on quality. By choosing these state-of-the-art wafer sets, companies can secure their supply chains and guarantee access to the latest advancements in material science. As industries continue to evolve, the need for dependable partnerships becomes paramount. Luag Ce Wafer Sets embody a commitment to innovation and excellence, making them the ideal choice for businesses looking to stay ahead in a competitive market. Embrace the future of manufacturing with these superior wafer sets and position your company for success in an ever-changing landscape.

Luag Ce Wafer Sets the Industry Standard Factory-Direct Excellence

| Feature | Specification | Application | Material Type |

|---|---|---|---|

| Thickness | 0.5 mm | Microelectronics | Silicon |

| Diameter | 200 mm | Semiconductors | GaAs |

| Wafer Grade | Prime | Optoelectronics | Silicon Carbide |

| Flatness | < 10 µm | MEMS Devices | Quartz |

| Surface Finish | Polished | Photonics | Silicon On Insulator |

Related Products