Affordable MgF2 Single Crystal Substrate from Reliable Factories

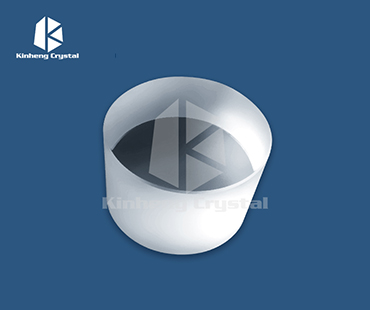

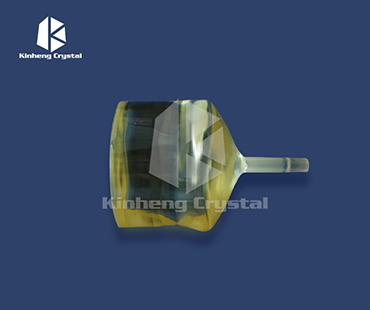

When I first explored the world of MgF2 Single Crystal Substrates, I realized the immense value they bring to various applications, especially in optics and electronics. You see, these substrates are not just essential for high-quality performance; they also cater to the needs of businesses seeking affordable solutions. That’s why I’ve partnered with reputable factories to ensure you get the best options without breaking the bank. Many industries require precision and reliability, and our MgF2 Single Crystal Substrates deliver exactly that. They're designed for easy integration into your projects, providing excellent optical clarity and minimal defects. If you’re looking to maintain high standards while keeping costs down, our products stand out in quality and price. Whether you're involved in research or production, these substrates are a smart choice that won't compromise your budget. Choose our offerings and experience the perfect blend of quality and affordability tailored for your business needs.

MgF2 Single Crystal Substrate For the Current Year Now Trending

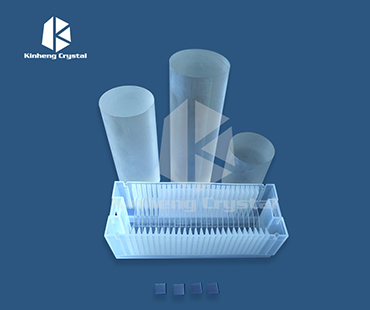

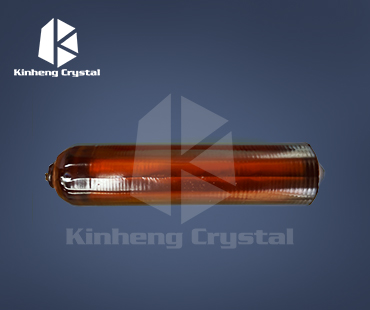

In the rapidly evolving landscape of crystal materials, MgF2 single crystal substrates are emerging as a trending choice for a wide range of applications in optics and electronics. Renowned for their excellent optical properties, these substrates offer a high degree of transparency and a low refractive index, making them ideal for various photonic devices, laser systems, and optical coatings. As industries strive for higher performance and efficiency, MgF2 substrates provide a reliable solution that supports advanced technological developments. The growing interest in MgF2 single crystal substrates among global buyers can be attributed to their versatility and superior characteristics compared to other materials. These substrates can be tailored to meet specific requirements, enabling their use in cutting-edge applications such as UV optics, infrared detectors, and scientific research. As the demand for precise and durable optical components continues to rise, sourcing high-quality MgF2 substrates from reputable suppliers has become paramount for businesses aiming to enhance their product offerings and maintain competitive advantage. As we move further into the current year, the focus on sustainable and innovative crystal materials will likely intensify. Buyers looking to leverage the benefits of MgF2 single crystal substrates should consider partnering with trusted manufacturers who prioritize quality and reliability. Investing in these materials not only supports the development of high-performance devices but also contributes to the broader advancement of technology across multiple industries, reinforcing the crucial role that crystal materials play in modern applications.

MgF2 Single Crystal Substrate For the Current Year Now Trending

| Property | Value |

|---|---|

| Crystal Structure | Cubic |

| Transparency Range | 130 nm - 7.5 µm |

| Refractive Index | 1.38 (at 600 nm) |

| Growth Method | Czochralski Method |

| Application | Optoelectronics and UV optics |

| Substrate Size | 2 inch, 3 inch |

| Typical Thickness | 0.5 mm - 1 mm |

| Thermal Conductivity | 1.3 W/(m·K) |

Related Products