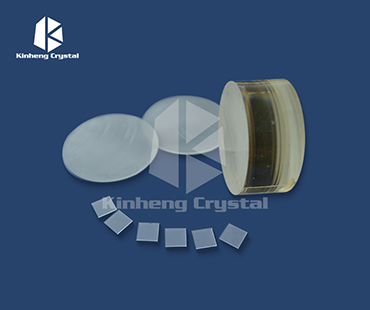

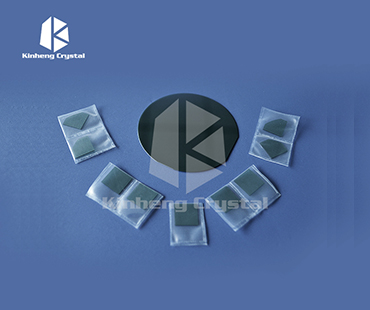

BaTiO3 Substrate with CE Certification from Reliable Factory

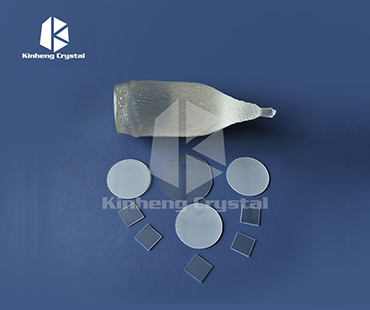

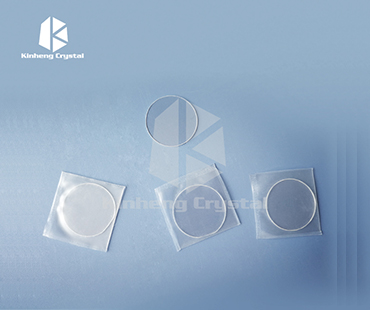

In today’s competitive market, I understand the importance of finding reliable materials for your production needs. Our BaTiO3 Substrate is crafted to meet the highest standards of quality and performance. With CE certification assuring compliance with European safety directives, you can trust that our substrates deliver reliable results for your applications. As a manufacturer, we pride ourselves on our state-of-the-art factory, where we utilize advanced technology and stringent quality control processes. This ensures that every batch of BaTiO3 Substrate remains consistent and meets the specific requirements of various industries. Whether you're in electronics, sensors, or other high-tech fields, our substrates can enhance your production processes and product outcomes. Let's elevate your projects together by choosing our trustworthy and certified BaTiO3 Substrate for your business needs. Reach out to me today to discuss how we can support your manufacturing goals!

BaTiO3 Substrate Dominates For the Current Year

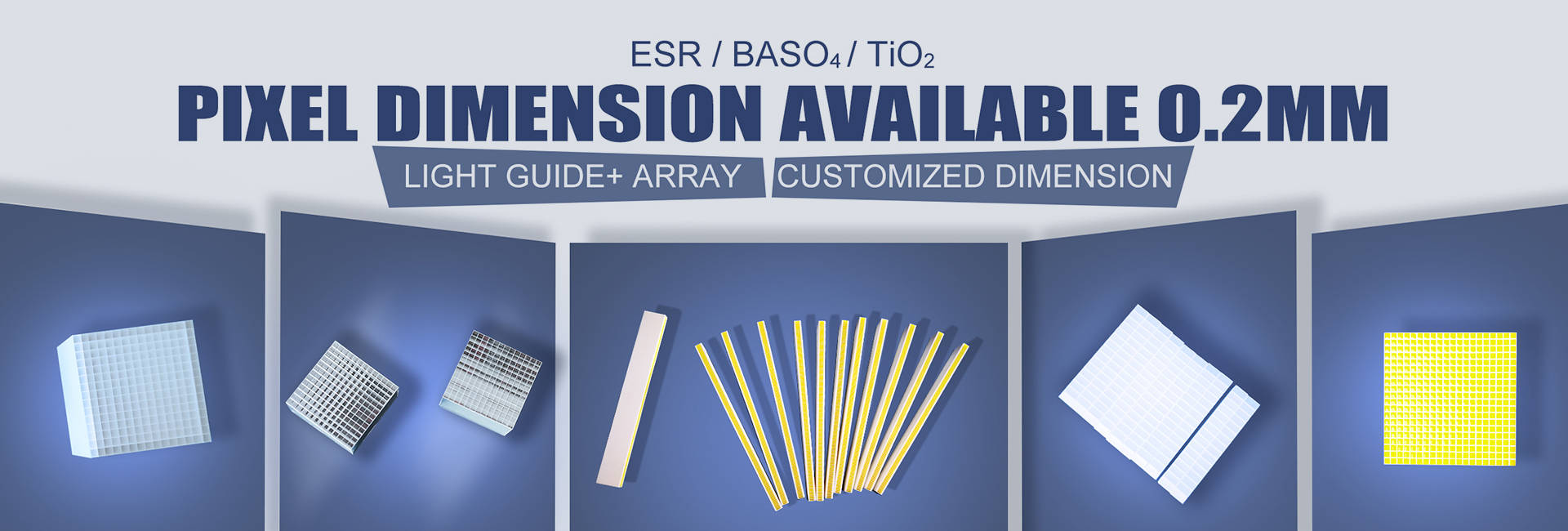

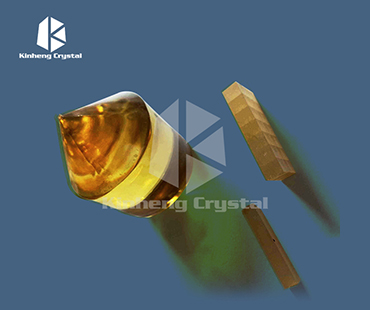

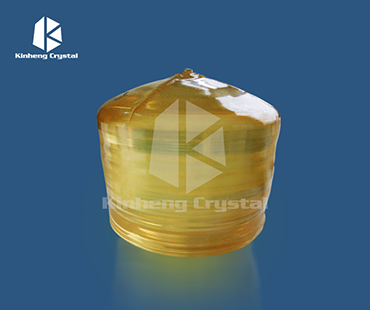

As the global market evolves, the demand for high-quality substrates is reaching new heights, with barium titanate (BaTiO3) substrates emerging as a dominant choice for various applications. Known for their excellent dielectric properties, piezoelectric capabilities, and thermal stability, BaTiO3 substrates are increasingly utilized in electronics, sensors, and advanced materials. Their ability to enhance device performance makes them an essential component for manufacturers aiming to stay competitive in the fast-paced landscape of technology. For procurement specialists, investing in BaTiO3 substrates not only ensures superior product quality but also aligns with the growing trend towards miniaturization and energy efficiency in electronic devices. With advancements in fabrication techniques, these substrates are available in various forms and sizes, catering to the specific needs of diverse applications. Companies looking to optimize their supply chain should consider incorporating BaTiO3 substrates to enhance their product offerings and meet the demands of evolving consumer preferences. In conclusion, as manufacturers and designers seek innovative solutions to address the challenges of modern technology, BaTiO3 substrates stand out as a reliable and high-performance option. Global buyers are encouraged to explore partnerships with suppliers specializing in this material to leverage its benefits and drive future growth in their respective markets. Embracing BaTiO3 substrates could be the key to unlocking new opportunities and maintaining a competitive edge in today’s dynamic environment.

BaTiO3 Substrate Dominates For the Current Year

| Parameter | Value | Unit |

|---|---|---|

| Permittivity | 1500 | εr |

| Dielectric Loss | 0.02 | - |

| Thickness | 0.5 | mm |

| Thermal Conductivity | 4.5 | W/(m·K) |

| Curie Temperature | 120 | °C |

| Substrate Size | 100 | mm |

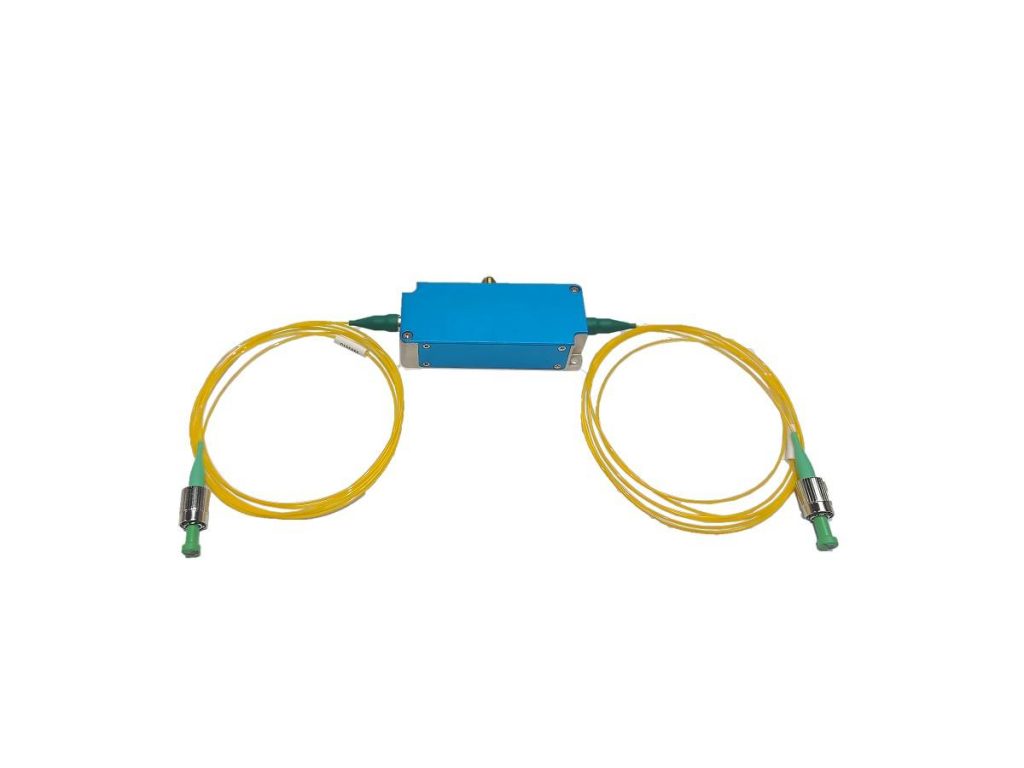

Related Products