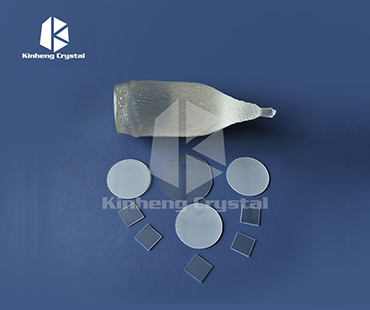

Custom DyScO3 Wafer Suppliers: Quality Solutions for Your Needs

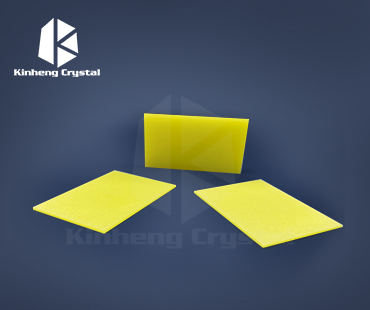

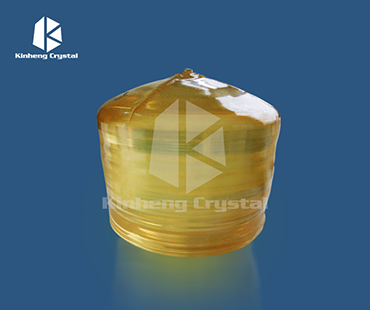

If you're in the market for high-quality DyScO3 wafers, you've come to the right place. As a leading supplier, I offer custom solutions tailored to meet your specific needs. Our DyScO3 wafers are crafted using advanced techniques, ensuring exceptional purity and performance for your applications. Whether you’re working in electronics, optics, or materials science, these wafers provide the reliability your projects demand. I understand that each buyer has unique requirements, so I’m committed to working closely with you to create the perfect product. From size to thickness, my customization options are designed to fit your specifications. With a dedicated support team, I make sourcing DyScO3 wafers a seamless experience, helping you to focus on innovation and growth in your business. Quality, reliability, and service are what I stand for—let’s take your projects to the next level together!

DyScO3 Wafer Dominates Now Trending

The market for DyScO3 wafers is gaining significant traction, becoming a focal point for industries seeking advanced materials for various high-tech applications. As the demand for efficient and reliable components escalates, DyScO3 wafers stand out due to their exceptional optical and electronic properties. Their remarkable ability to enhance performance in cutting-edge devices makes them a highly sought-after resource in sectors including telecommunications, aerospace, and electronics. As global procurement strategies evolve, understanding the intricacies of sourcing quality DyScO3 wafers is crucial. Buyers must focus on suppliers that prioritize quality control and provide consistent, high-purity materials. The growing trend of integrating DyScO3 wafers into next-generation technologies signifies a shift in how manufacturers approach material selection. By investing in these innovative materials, businesses can enhance their product offerings, streamline production processes, and ultimately gain a competitive edge in an increasingly aggressive market. The rise of DyScO3 wafers not only emphasizes the importance of material science but also illustrates the interconnectedness of today's global supply chain. As industries embrace new technologies and products, the successful procurement of these materials will play a key role in the advancement of various sectors. Stakeholders must remain vigilant and adaptable to capitalize on this trending material, ensuring that they are well-positioned to leverage the opportunities it presents.

DyScO3 Wafer Dominates Now Trending

| Parameter | Value | Unit |

|---|---|---|

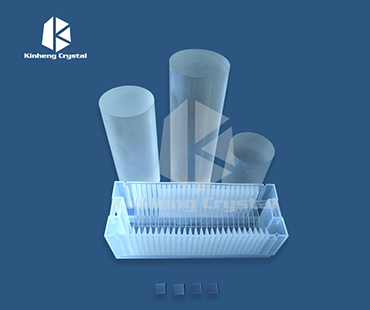

| Thickness | 500 | µm |

| Diameter | 200 | mm |

| Crystallinity | High | - |

| Purity | 99.999% | - |

| Growth Method | MOCVD | - |

| Substrate Material | SrTiO3 | - |

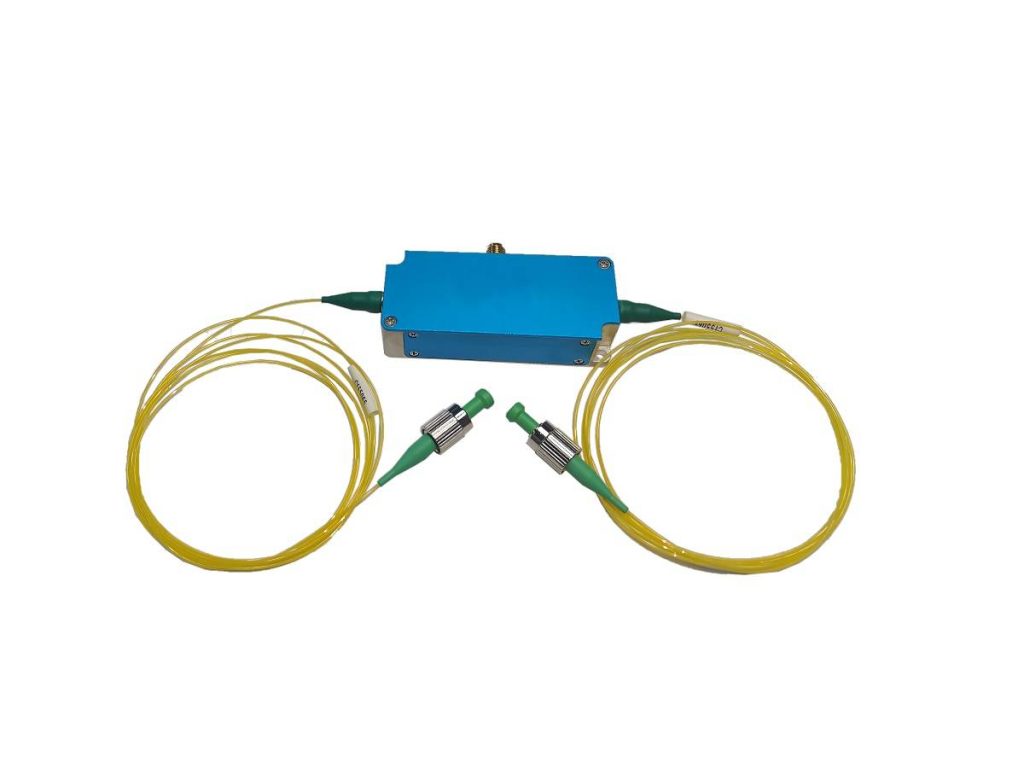

| Typical Applications | MEMS, Optoelectronics | - |

Related Products