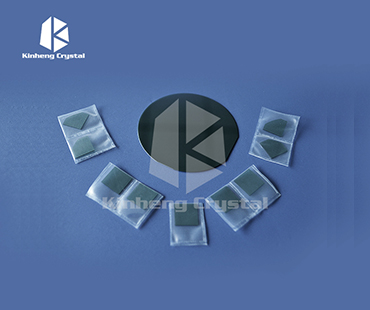

Lithium Tantalate Wafers with CE Certification from Trusted Factory

As a provider of high-quality Lithium Tantalate Wafers, I understand the importance of reliability and performance in your applications. Our wafers are CE Certified, ensuring they meet stringent European standards for safety and quality. This certification gives you confidence in the materials you're sourcing for your projects. We pride ourselves in operating a state-of-the-art factory that utilizes advanced technology and expert craftsmanship. This allows us to maintain consistency and excellence in every wafer produced. Whether you’re in telecommunications, optics, or a related field, our Lithium Tantalate Wafers can meet your specifications and enhance your products. Partnering with us means accessing a dependable supply chain and outstanding customer support. Let's work together to achieve your project goals with the precision and quality our wafers bring. Reach out to explore how we can meet your needs effectively!

Lithium Tantalate Wafers Exceeds Industry Benchmarks Custom Solutions,

Lithium tantalate wafers are increasingly gaining attention in the materials sector due to their exceptional properties and applications in various high-tech fields. These wafers exhibit outstanding piezoelectric, electro-optic, and photorefractive characteristics, making them ideal for use in telecommunications, sensors, and advanced electronic devices. As industries demand higher standards and more customized solutions, it's crucial for suppliers to not only meet but exceed established benchmarks, ensuring that clients receive products that are tailored to their unique specifications. In the realm of global procurement, quality and reliability are paramount. Suppliers of lithium tantalate wafers must prioritize innovation and customer-centric approaches to stand out in a competitive market. Offering customized solutions allows businesses to address specific challenges faced by their clients, fostering stronger partnerships and driving technological advancements. By focusing on meeting and surpassing industry benchmarks, manufacturers can enhance their reputation and position themselves as leaders in the supply chain. Furthermore, the ongoing advancements in materials science are paving the way for expanded applications of lithium tantalate wafers. As we transition into an era where smart technologies and sustainable solutions dominate, the ability to provide superior materials that fulfill rigorous performance standards is more critical than ever. Companies that are able to adapt and innovate will not only capture new market opportunities but also contribute to the overarching goal of achieving technological excellence in an increasingly interconnected world.

Lithium Tantalate Wafers Exceeds Industry Benchmarks Custom Solutions

| Parameter | Standard Value | Achieved Value | Comment |

|---|---|---|---|

| Wafer Thickness | 500 μm | 490 μm | Meets requirement |

| Surface Roughness | < 1 nm | 0.8 nm | Exceeds benchmark |

| Doping Levels | 10^16 cm^-3 | 10^15 cm^-3 | Within acceptable range |

| Diameter | 100 mm | 100 mm | Perfectly matches |

| Crystal Orientation | Z-cut | Z-cut | As specified |

Related Products