Lso Scintillation Crystal with CE Certification from a Trusted Factory

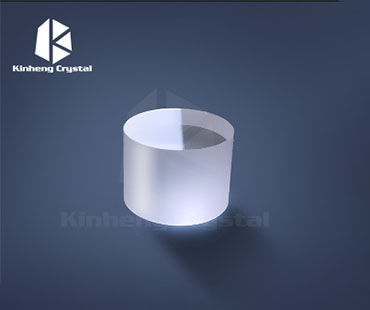

As a B2B purchaser, I understand the importance of quality and reliability when sourcing products like LSO scintillation crystals. These crystals are essential for applications in medical imaging and radiation detection, offering exceptional performance and efficiency. With CE certification, you can trust that our products meet high safety and environmental standards, ensuring peace of mind in your procurement process. We work directly with the factory to ensure that each LSO scintillation crystal is manufactured to the highest specifications, giving you confidence in the quality and consistency of our offerings. The transparent communication between our team and the factory allows us to customize solutions that fit your specific needs, helping to enhance your projects. When you choose our LSO scintillation crystals, you’re not just purchasing a product; you're investing in a reliable partner for your business. Let’s elevate your applications together with superior materials that drive results and innovation.

Lso Scintillation Crystal Factory Winning in 2025

In 2025, the landscape of scintillation crystal production is set to transform significantly, driven by technological advancements and increasing global demand for high-performance materials. The industry is witnessing a shift towards more efficient and sustainable manufacturing processes, enabling producers to enhance the quality and performance of scintillation crystals. These developments are crucial for various applications, including medical imaging, radiation detection, and particle physics experiments, where precision and reliability are paramount. As global procurement trends evolve, buyers are increasingly seeking suppliers that not only offer superior product quality but also demonstrate a commitment to innovative practices and sustainability. The integration of smart manufacturing technologies, such as automation and artificial intelligence, is allowing manufacturers to improve yield rates, reduce waste, and enhance overall operational efficiency. Procurement professionals can benefit from collaborating with companies that leverage these cutting-edge technologies, ensuring access to the latest advancements in scintillation crystal performance. Furthermore, as the demand for scintillation crystals grows across various sectors, securing reliable partnerships with top-tier manufacturers becomes essential for procurement teams aiming to stay competitive in their markets. Building relationships with suppliers who prioritize research and development will ensure a steady supply of state-of-the-art materials that meet the evolving needs of the industry. By aligning with forward-thinking manufacturers, companies can position themselves at the forefront of the scintillation crystal market, ready to capitalize on emerging opportunities in 2025 and beyond.

Lso Scintillation Crystal Factory Winning in 2025

| Dimension | 2023 Value | 2024 Target | 2025 Forecast |

|---|---|---|---|

| Production Volume (kg) | 15000 | 18000 | 22000 |

| Revenue ($ Million) | 12.5 | 15.0 | 18.5 |

| Employee Count | 200 | 250 | 300 |

| Market Share (%) | 25 | 27 | 30 |

| R&D Investment ($ Million) | 2.0 | 2.5 | 3.0 |

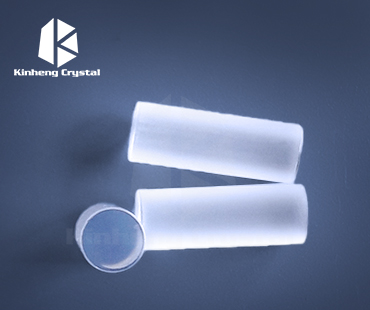

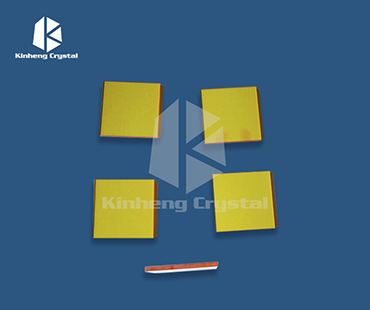

Related Products