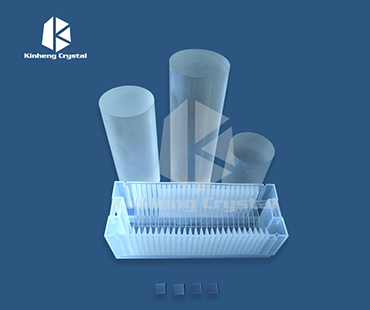

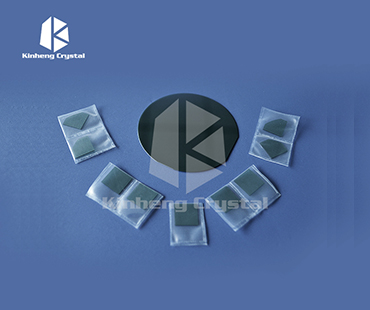

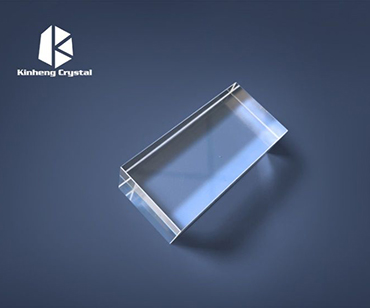

Custom MgF2 Substrate Suppliers for Precision Applications

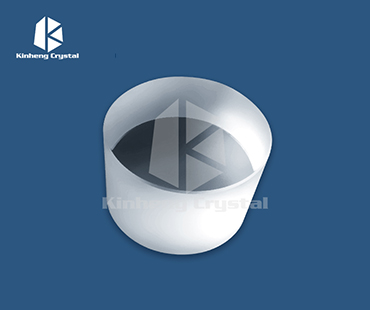

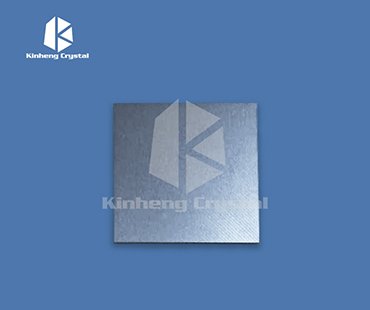

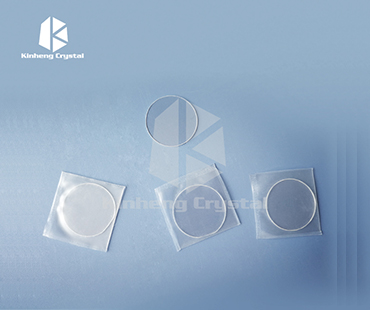

As a B2B purchaser seeking high-quality substrates, I understand the importance of reliable suppliers for MgF2 substrates. These custom substrates are essential for various applications, including optics and thin films. The unique properties of MgF2 make it an ideal choice for those of us needing superior performance in optical components. When I partner with trusted suppliers, I look for tailored solutions that meet my project's specific requirements. With a range of thicknesses and dimensions available, these custom MgF2 substrates can be produced to fit any design need. I appreciate the expertise and flexibility offered by leading suppliers who can deliver high-purity materials with fast turnaround times. Choosing the right MgF2 substrate can make a significant difference in the efficiency and effectiveness of my projects. That's why I prioritize working with suppliers who understand my needs and can deliver quality products that ensure success.

MgF2 Substrate Industry Giant Sets the Industry Standard

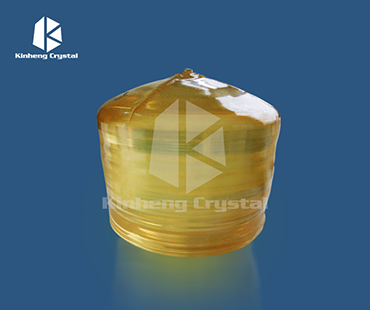

In the rapidly evolving landscape of optics and photonics, the MgF2 substrate has emerged as a cornerstone material, setting the stage for advancements across various applications, from high-quality lens manufacturing to cutting-edge optical coatings. As industry leaders focus on enhancing performance and reliability, a new giant has materialized, establishing benchmarks that drive efficiency, quality, and innovation in the MgF2 substrate sector. This entity's commitment to superior manufacturing processes ensures that its products meet stringent quality standards, positioning them as the go-to choice for global suppliers. By leveraging advanced technology and continuous research and development, the company not only enhances product performance but also reduces costs for OEMs and manufacturers alike. This results in a streamlined supply chain that benefits not just the producers but also end-users seeking reliable optical components. Moreover, the rise of this industry giant emphasizes the importance of collaboration and partnership in fostering innovation. As it sets the standard for MgF2 substrates, global buyers are encouraged to engage with suppliers that are committed to excellence and sustainability. Access to high-quality substrates is crucial for maintaining competitive advantages in the global market, and aligning with an established leader ensures that procurement needs are met effectively, paving the way for future advancements in optical technology.

MgF2 Substrate Industry Giant Sets the Industry Standard

| Parameter | Description | Value | Unit |

|---|---|---|---|

| Thickness | Thickness of MgF2 substrate | 0.5 - 1.0 | mm |

| Diameter | Diameter of substrate | 1 - 4 | inch |

| Refractive Index | Refractive index of MgF2 | 1.38 | @ 550 nm |

| Transmission | Optical transmission percentage | 90 | % |

| UV Cutoff | Cutoff wavelength for UV range | 125 | nm |

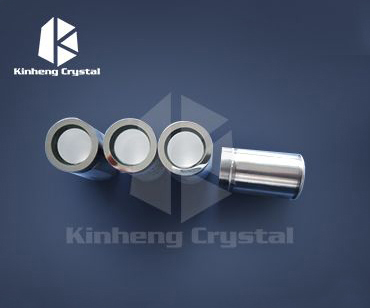

| Usage | Typical applications of MgF2 substrates | Optical coatings, lasers, and photonics | |

Related Products