Wholesale Single Crystal Substrate Manufacturers for High-Quality Solutions

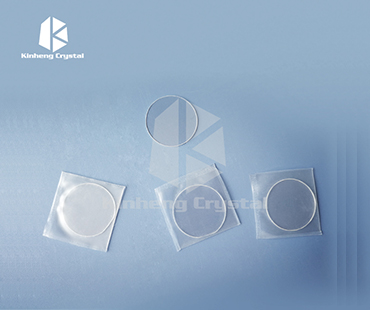

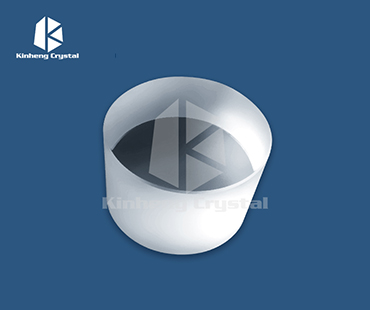

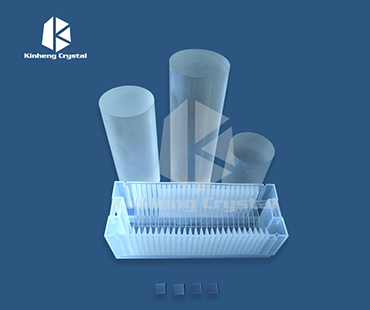

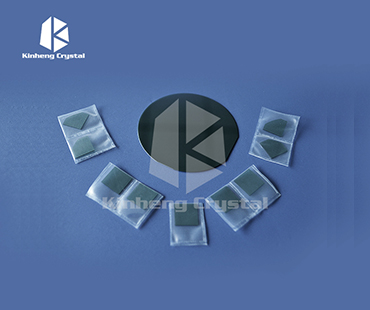

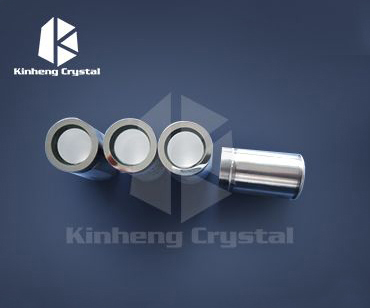

Are you in the market for high-quality single crystal substrates? As a reliable supplier, I understand the unique needs of manufacturers seeking top-notch materials at wholesale prices. Our single crystal substrates are engineered to meet the rigorous standards of various applications, ensuring optimal performance and reliability. I know how crucial it is for you to find a trustworthy manufacturer that can consistently provide these specialized products. Our substrates are crafted using state-of-the-art technology and undergo strict quality control to guarantee purity and precision. Whether you’re working in optics, electronics, or other advanced fields, our substrates will help elevate your projects to new heights. With flexible ordering options and competitive pricing, we cater to both large and small-scale buyers. Let's connect and discuss how our single crystal substrates can meet your manufacturing needs! Your satisfaction is paramount, and we're here to support your success.

Single Crystal Substrate Manufacturer Factory

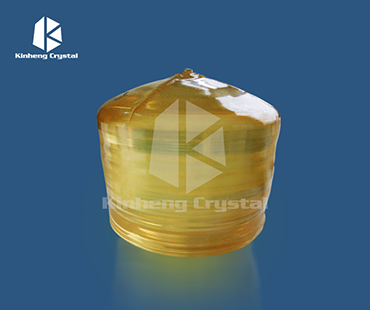

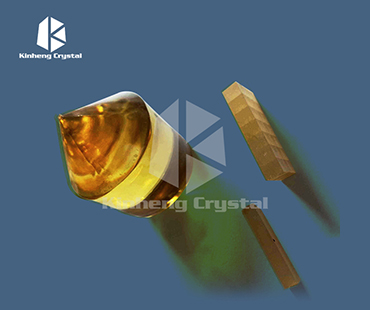

In the advanced world of semiconductor manufacturing and high-performance electronics, the demand for single crystal substrates is on the rise. These substrates play a crucial role in enhancing the efficiency and functionality of electronic devices. By providing the foundational layer for electronic components, they ensure superior performance, improved thermal conductivity, and reduced defects, which are vital for applications ranging from solar cells to LED technology. For global buyers, the search for a reliable supplier of high-quality single crystal substrates has never been more critical. Established expertise in material science and innovative production techniques are essential when selecting a manufacturer. It is important to consider factors such as production capacity, quality assurance processes, and certifications. A reputable factory typically employs cutting-edge technology and skilled professionals to manufacture substrates that meet international standards. By collaborating with such a manufacturer, procurement teams can ensure they are sourcing products that not only fulfill their technical specifications but also support their commitment to sustainability and performance excellence. In an increasingly interconnected market, forming partnerships with manufacturers who can deliver consistent quality while adapting to evolving demands is key. The capability to customize substrate dimensions and properties according to specific application requirements enhances competitiveness. As we move toward smarter technology solutions, the role of high-quality single crystal substrates remains pivotal, underscoring the importance of selecting the right manufacturer to drive innovation and success in the electronic and semiconductor industries.

Single Crystal Substrate Manufacturer Factory

| Material | Crystal Structure | Dimensions (mm) | Orientation | Tolerance |

|---|---|---|---|---|

| Silicon | Diamond Cubic | 100 x 100 x 0.5 | (100) | ±0.05 |

| Gallium Arsenide | Zinc Blende | 50 x 50 x 0.3 | (100) | ±0.02 |

| Sapphire | Trigonal | 75 x 75 x 0.5 | (0001) | ±0.03 |

| Lithium Niobate | Trigonal | 100 x 100 x 0.5 | (001) | ±0.04 |

| Barium Titanate | Cubic | 100 x 100 x 0.5 | (100) | ±0.05 |

Related Products