Leading CdZnTe Wafer Manufacturer in China for Advanced Technology

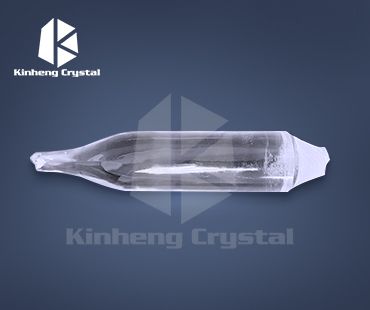

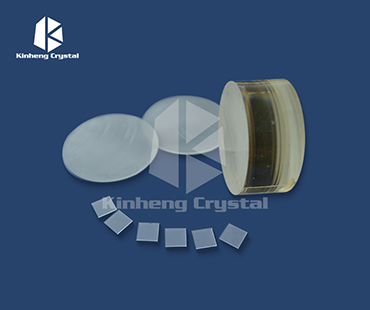

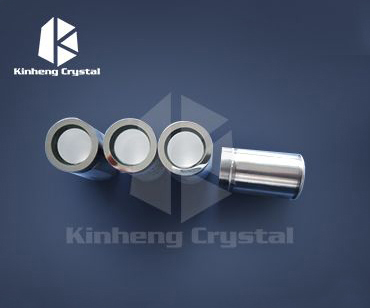

When searching for high-quality CdZnTe wafers, I understand the importance of finding a reliable manufacturer in China. Our CdZnTe wafers are specially designed for applications in the semiconductor and photovoltaic industries. With exceptional purity and uniformity, these wafers meet stringent industry standards and are perfect for advanced research and production. We pride ourselves on being a leading manufacturer, committed to delivering products that enhance your projects. Our dedicated team ensures that every wafer undergoes rigorous testing to guarantee optimal performance. Whether you're in need of standard sizes or custom specifications, we can accommodate your requirements with precision. Choosing our CdZnTe wafers means partnering with a manufacturer that values quality and reliability. Let's work together to elevate your projects and achieve exceptional results in your semiconductor applications.

CdZnTe Wafer Manufacturers You Can Rely On From Concept to Delivery

When sourcing high-quality CdZnTe wafers, reliability is key. The journey from concept to delivery involves a meticulous process where precision and quality need to be guaranteed at every stage. Manufacturers who specialize in CdZnTe materials understand the nuances of crystal growth, cutting, and polishing, ensuring that the wafers meet the specific requirements of your applications, be it in the field of radiation detection, photovoltaic cells, or infrared optics. What sets apart leading CdZnTe wafer manufacturers is their commitment to innovation and quality control. Utilizing advanced production techniques and state-of-the-art facilities, they can produce wafers that not only conform to international standards but also cater to personalized specifications. This adaptability is crucial for organizations looking to leverage the unique properties of CdZnTe crystals in cutting-edge technologies. Additionally, robust supply chain management ensures that orders are fulfilled on time, providing peace of mind to procurement managers worldwide. Furthermore, collaborating with a trustworthy manufacturer allows for seamless communication and expert guidance throughout the procurement process. From initial inquiries to technical support during the installation phase, these manufacturers strive to build long-term partnerships that foster mutual growth. With their expertise and dedication to customer satisfaction, you can confidently move forward with your projects, knowing you have a reliable partner by your side every step of the way.

CdZnTe Wafer Manufacturers You Can Rely On From Concept to Delivery

| Manufacturer Location | Technology Expertise | Product Range | Quality Certifications | Lead Time |

|---|---|---|---|---|

| USA | Advanced Crystal Growth | Standard and Custom Wafer Sizes | ISO 9001, ISO 14001 | 4-6 Weeks |

| Germany | Materials Characterization | Thin Films, Multi-Layer Structures | TS 16949 | 3-5 Weeks |

| Japan | Semiconductor Processing | High Purity Single Crystals | JIS Q 9001 | 5-7 Weeks |

| South Korea | Innovative Fabrication Techniques | Custom Substrates, Prototypes | ISO 9001, CE | 6-8 Weeks |

| China | Mass Production Capabilities | Various Wafer Thicknesses | ISO 13485 | 2-4 Weeks |

Related Products