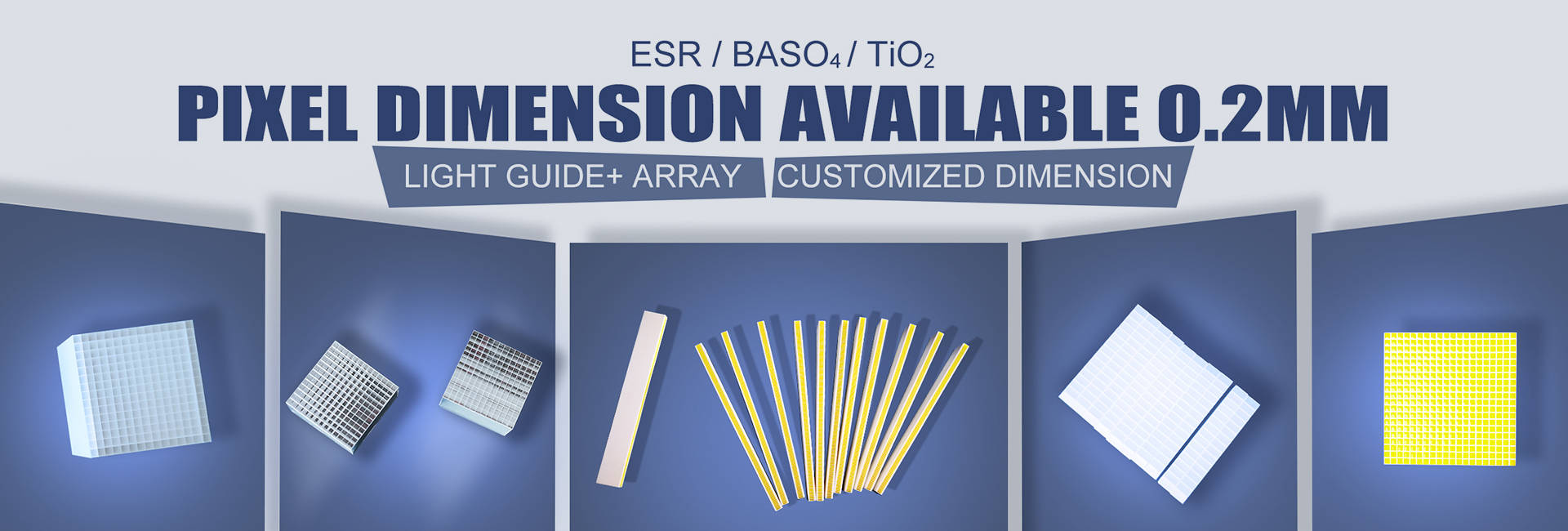

Wholesale Gagg Ce Matrix: Top Manufacturers for Quality Solutions

When it comes to top-quality Gagg Ce Matrix, I’ve found that partnering with the right manufacturers makes all the difference. This innovative product stands out in the wholesale market, providing exceptional performance that can elevate any project. I appreciate the reliability and efficiency of the Gagg Ce Matrix, which is designed to meet the demands of diverse industries. The seamless integration into existing workflows means less downtime and better productivity for my business. Knowing I can source this product directly from trustworthy manufacturers gives me peace of mind. Whether you’re scaling operations or just starting out, investing in the Gagg Ce Matrix can set you apart from competitors. I’ve seen firsthand how it enhances productivity and quality, making it a must-have in every warehouse. Let's take our businesses to the next level with this exceptional product!

Gagg Ce Matrix Factory Custom Solutions,

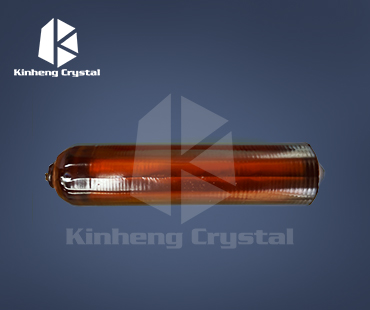

In recent years, the demand for high-quality crystal materials has surged globally, driven by advancements in technology and the growing emphasis on premium products across various industries. Understanding the specific needs of diverse sectors—from electronics to jewelry and architectural design—has led to a rise in tailored solutions that cater to these varied applications. One focal point in this evolution is the Gagg Ce Matrix, a versatile and innovative solution designed to meet the unique specifications of clients worldwide. The Gagg Ce Matrix embodies a commitment to customization, offering businesses the opportunity to integrate crystal materials into their products seamlessly. Whether you are looking for unique designs, specific sizes, or particular functionalities, this approach not only enhances the aesthetic appeal but also optimizes performance. By collaborating closely with manufacturers, purchasers can access a wealth of expertise that ensures the final product not only meets but exceeds industry standards. As global procurement continues to evolve, the ability to source customized materials that align with specific project requirements will set businesses apart. The focus is shifting towards sustainable sourcing and efficient supply chains, making it imperative for buyers to engage with manufacturers that prioritize quality and innovation. By investing in customized solutions, companies can leverage competitive advantages, foster creativity, and ultimately drive success in their respective markets.

Gagg Ce Matrix Factory Custom Solutions

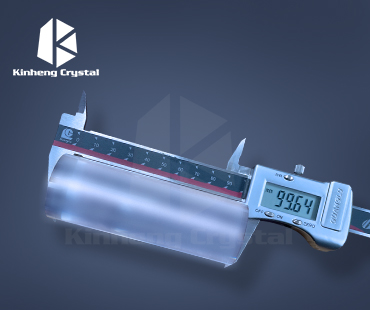

| Dimension | Description | Value |

|---|---|---|

| Material Type | High-strength steel alloy | AISI 4130 |

| Production Method | Advanced welding and fabrication | Automated Welding |

| Thickness | Material thickness used | 10 mm |

| Surface Treatment | Coatings applied for durability | Powder Coating |

| Custom Features | Specialized designs for specific needs | Modular Design |

| Testing Standards | Quality assurance protocols | ISO 9001 |

Related Products