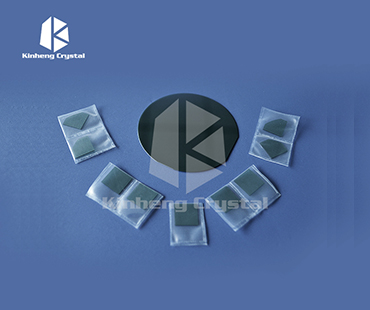

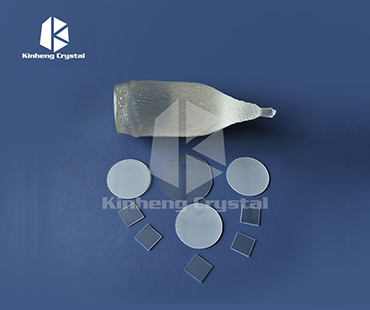

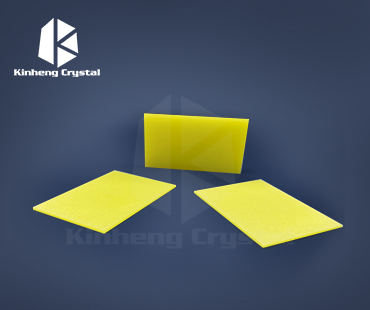

Lyso Ce Wafer from Leading Manufacturer in China for Quality Solutions

Are you in search of high-quality Lyso Ce Wafers? As a trusted manufacturer based in China, I understand the importance of supplying reliable products to meet your business needs. Our Lyso Ce Wafers are meticulously crafted to ensure superior efficacy, making them a perfect addition to your inventory. Whether you're involved in pharmaceuticals or research laboratories, these wafers provide consistent performance and meet rigorous quality standards. We prioritize both quality and efficiency in our production processes, ensuring you receive a product that aligns with your requirements. Let’s work together to support your business goals! By choosing our Lyso Ce Wafers, you’re not just purchasing a product, but partnering with a dedicated manufacturer committed to your success. If you have any questions about specifications or bulk ordering, I'm here to help you navigate through your choices. Reach out today, and let's elevate your offerings with our top-notch Lyso Ce Wafers!

Lyso Ce Wafer Ahead of the Curve Sets the Industry Standard

In the rapidly evolving landscape of semiconductor manufacturing, the need for innovative materials is paramount. Among these, the Lyso Ce Wafer emerges as a groundbreaking product that not only meets but sets new benchmarks in the industry. With its superior quality and performance, the Lyso Ce Wafer is designed to enhance efficiency and yield in production processes, ultimately leading to a more sustainable and cost-effective approach for manufacturers worldwide. What makes the Lyso Ce Wafer stand out is its unique composition and manufacturing technique, which ensures exceptional structural integrity and consistency. This product is tailored to meet the specific demands of high-precision applications, making it an ideal choice for global procurement specialists looking for reliable sourcing options. As manufacturers face increasing pressure to optimize their supply chains, the Lyso Ce Wafer presents a strategic advantage, providing both quality assurance and competitive pricing. Embracing innovations like the Lyso Ce Wafer is crucial for companies aiming to remain ahead of the competition. By integrating advanced materials into their production lines, businesses can improve their overall operational efficiency, resulting in enhanced profitability and market agility. The shift towards high-performance materials is not just a trend—it's a necessity for future-proofing manufacturing capabilities in a dynamic global economy.

Lyso Ce Wafer Ahead of the Curve Sets the Industry Standard

| Feature | Specification | Application | Performance Indicator |

|---|---|---|---|

| Thickness | 200 µm | Semiconductor Devices | Low Resistance |

| Diameter | 300 mm | Photovoltaics | High Efficiency |

| Material | Silicon | Microelectronics | Thermal Stability |

| Surface Finish | Polished | LED Manufacturing | Optical Clarity |

| Conductivity | N-type | Integrated Circuits | High Current Capability |

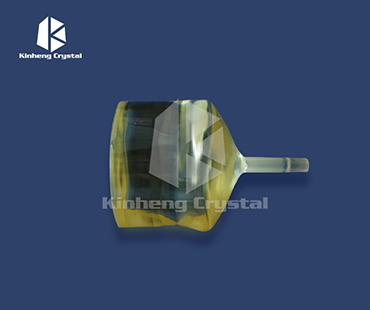

Related Products