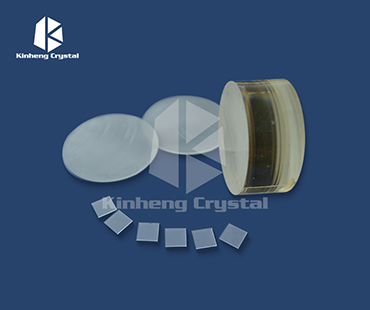

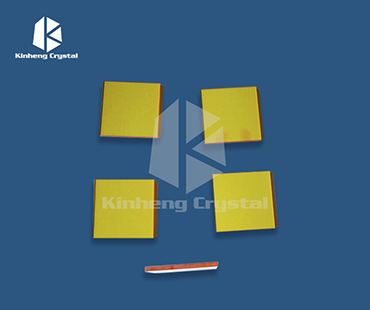

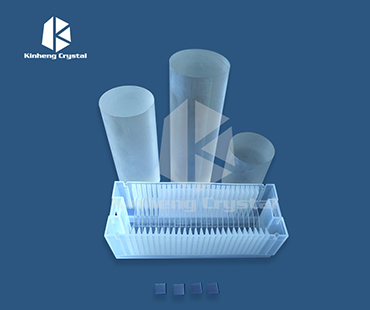

Cheap MgAl2O4 Substrate from Reliable Factories for Your Projects

When I found the MgAl2O4 substrate, I knew it was the perfect solution for my manufacturing needs. This high-quality substrate is not only durable but also affordable, making it an unbeatable choice for factories looking to cut costs without sacrificing quality. I've seen firsthand how it enhances performance in various applications, which is why I always recommend it to my colleagues in the industry. By choosing the MgAl2O4 substrate, you’re investing in a product that promises reliability and efficiency. Plus, for those of us in the B2B space, finding a supplier that offers this substrate at a cheap price is essential. I’ve sourced from multiple factories, and I’m consistently impressed with the competitive pricing and excellent service. If you’re in need of a cost-effective substrate that meets the demands of modern manufacturing, the MgAl2O4 option is a smart choice.

MgAl2O4 Substrate Sets the Industry Standard Guarantees Peak Performance

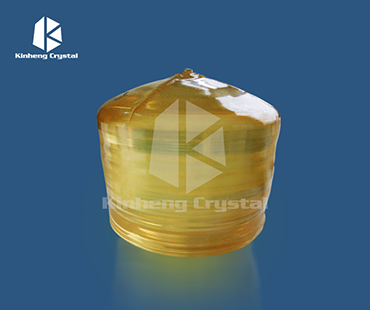

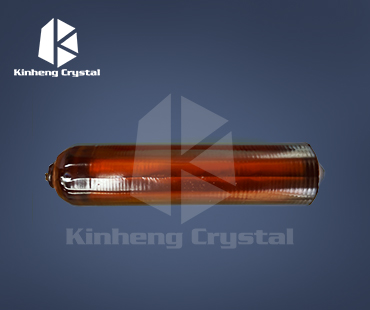

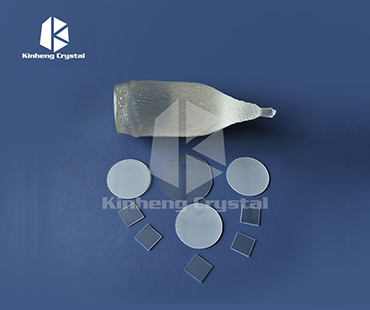

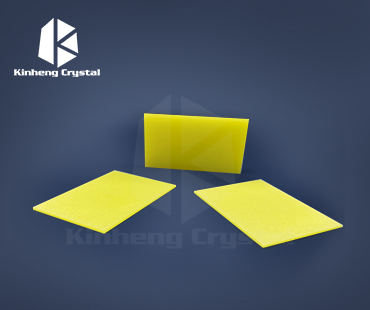

The innovative use of magnesium aluminate (MgAl2O4) substrates has set a new benchmark in the industry, promising unparalleled performance and reliability. As global demand for cutting-edge electronic and photonic applications grows, the choice of substrate material has become crucial for manufacturers aiming to enhance the efficiency and longevity of their products. MgAl2O4, with its exceptional thermal stability and electrical insulation properties, stands at the forefront of these materials, ensuring peak performance across various applications. This substrate offers notable advantages, including a high melting point and excellent mechanical strength, making it an ideal candidate for high-frequency and high-power devices. Its low thermal expansion coefficient minimizes stress on the components, greatly reducing the risk of deformation or failure during operation. As a result, manufacturers utilizing MgAl2O4 substrates can achieve superior thermal management, leading to improved device performance and increased operational lifespans. In a highly competitive market, where performance and reliability are paramount, adopting MgAl2O4 substrates is not just a technical decision—it's a strategic one. Businesses that prioritize these advanced materials can ensure their products meet the rigorous demands of modern applications, solidifying their position as industry leaders. By choosing MgAl2O4, manufacturers are not only investing in quality but also paving the way for innovation and excellence in their respective fields.

MgAl2O4 Substrate Sets the Industry Standard Guarantees Peak Performance

| Property | Value | Description |

|---|---|---|

| Material Type | Spinel | A ceramic compound made of magnesium aluminate. |

| Thermal Conductivity | ~ 30 W/m·K | High thermal conductivity enabling efficient heat dissipation. |

| Dielectric Constant | ~ 9.4 | Low dielectric constant suitable for high-frequency applications. |

| Coefficient of Thermal Expansion | ~ 7.4 x 10^-6 K^-1 | Low CTE for good thermal stability in various applications. |

| Mechanical Strength | > 300 MPa | Excellent mechanical strength for demanding environments. |

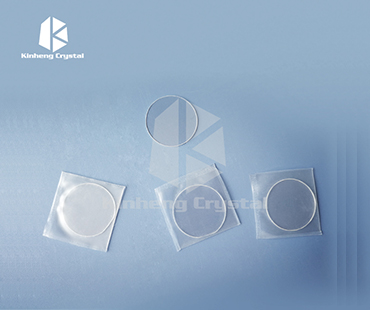

| Optical Transparency | Transparent to visible light | Suitable for optical applications thanks to its transparency. |

Related Products