SIC Single Crystal Substrate Manufacturer in China | High-Quality Solutions

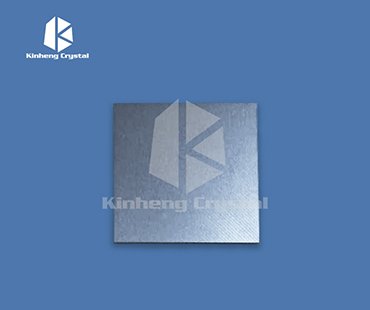

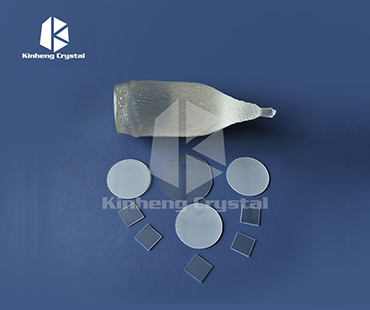

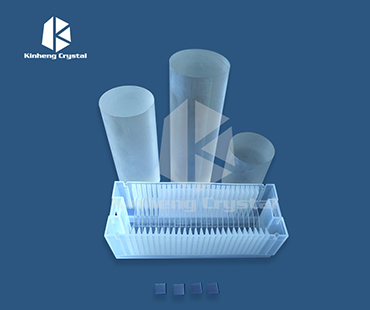

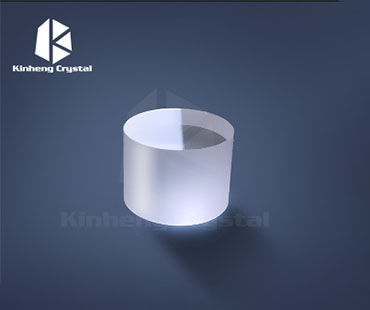

As a professional in the field, I've seen first-hand how essential SIC single crystal substrates are for advanced semiconductor applications. Sourced directly from reliable manufacturers in China, our substrates deliver outstanding thermal conductivity and excellent crystal quality, ensuring optimal performance in your projects. I understand the importance of precision and reliability in your supply chain, and I can assure you that our products meet the highest industry standards. With a variety of sizes and specifications available, we cater specifically to your needs, whether you’re in research or production. When you choose our SIC single crystal substrates, you’re not just selecting a product; you’re investing in quality and professionalism that supports your business objectives. Let’s collaborate to bring your technological innovations to life!

SIC Single Crystal Substrate Dominates Exceeds Industry Benchmarks

In the rapidly evolving landscape of semiconductor materials, single crystal substrates have emerged as a pivotal component in enhancing performance metrics across various applications. The exceptional qualities of SIC (Silicon Carbide) single crystal substrates are setting new industry benchmarks, demonstrating superior thermal conductivity, mechanical strength, and a breakdown voltage that far exceeds traditional silicon substrates. These characteristics make SIC an ideal choice for high-power and high-frequency devices, driving innovation in sectors such as automotive, telecommunications, and renewable energy. As global demand escalates for more efficient and reliable semiconductor solutions, the advantages of SIC single crystal substrates become increasingly evident. Their capability to operate at elevated temperatures and voltages allows for the development of devices that are not only more efficient but also more durable, reducing the need for frequent replacements and maintenance. This shift helps manufacturers meet the stringent requirements of modern technologies while optimizing their production processes and minimizing energy consumption. For procurement specialists seeking cutting-edge materials to enhance their product offerings, SIC single crystal substrates present a unique opportunity. By leveraging these advanced materials, companies can improve their competitive edge and address the growing demands for high-performance electronics in today's market. Investing in these innovative substrates is not just a response to current industry trends but a proactive step towards shaping a sustainable and technologically advanced future.

SIC Single Crystal Substrate Dominates Exceeds Industry Benchmarks

| Parameter | SIC Single Crystal Substrate | Industry Benchmark |

|---|---|---|

| Thermal Conductivity (W/mK) | 200 | 150 |

| Dielectric Breakdown Voltage (MV/cm) | 15 | 10 |

| Mechanical Strength (GPa) | 400 | 350 |

| Surface Roughness (nm) | 0.2 | 0.5 |

| Growth Rate (μm/hr) | 3.5 | 2.5 |

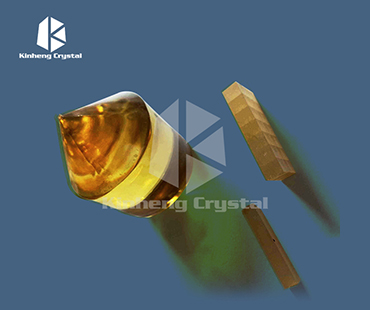

Related Products