Sapphire Wafer with CE Certification from Leading Factory Manufacturers

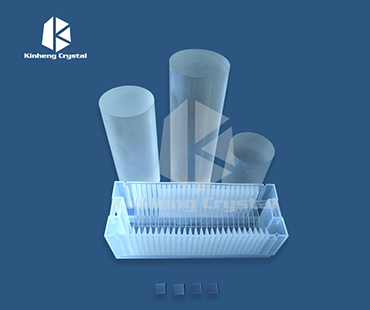

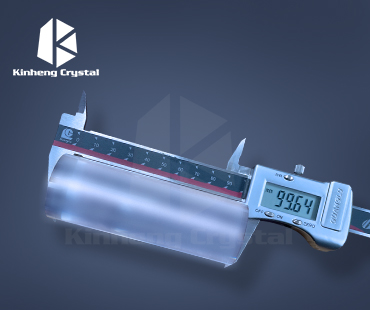

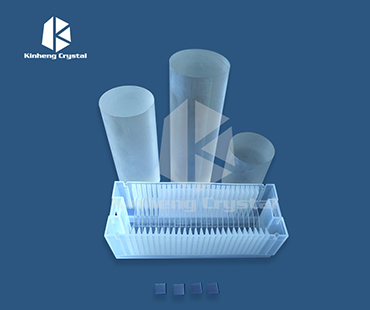

When I think about high-quality sapphire wafers, I know that CE certification is a vital aspect for B2B purchasers like you. It assures the product meets rigorous European standards of safety and performance. Our sapphire wafers are manufactured in a state-of-the-art factory that emphasizes precision and reliability. We've invested in advanced technology and skilled labor, ensuring each wafer meets the needs of industries ranging from electronics to optics. From using our sapphire wafers, you'll find they offer exceptional durability and thermal stability. That's crucial when you need consistent performance in demanding applications. Plus, working with a trusted supplier means peace of mind, knowing you’re sourcing from a factory that prioritizes quality. If you're looking to scale your production or enhance the performance of your devices, our certified sapphire wafers could be the solution you need. Let’s elevate your business together!

Sapphire Wafer Is The Best Where Innovation Meets 2025

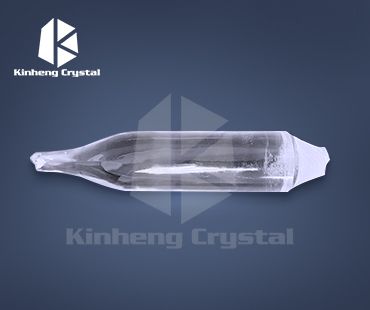

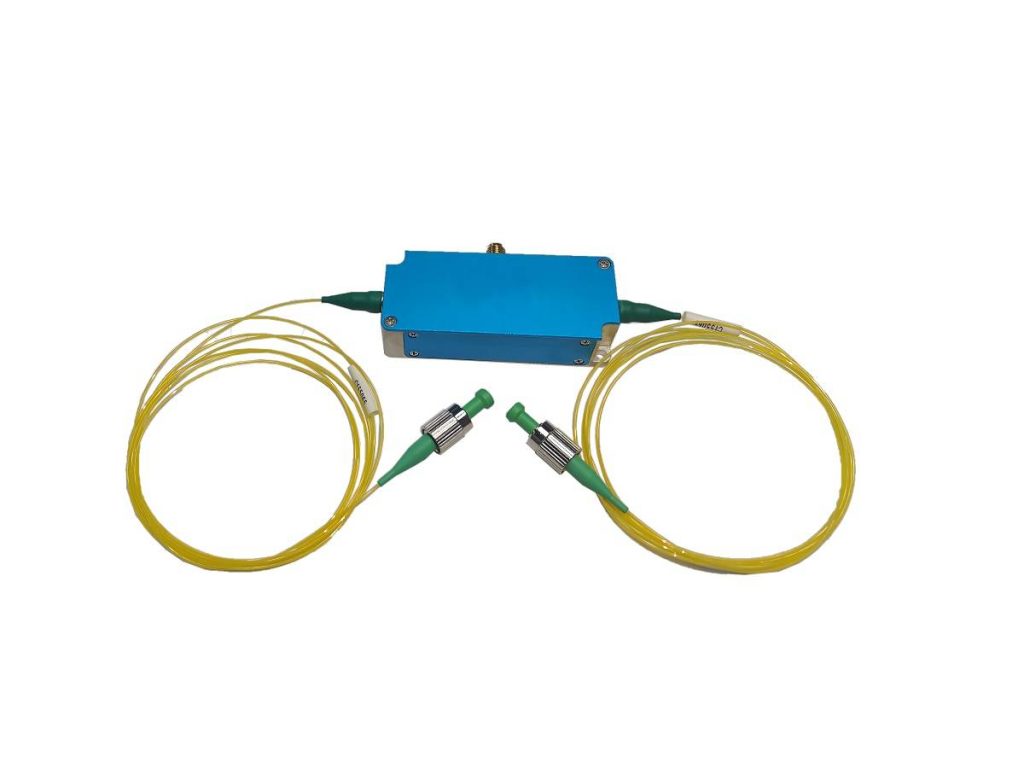

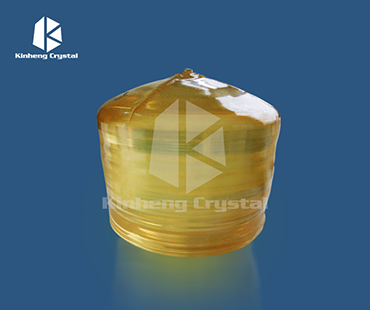

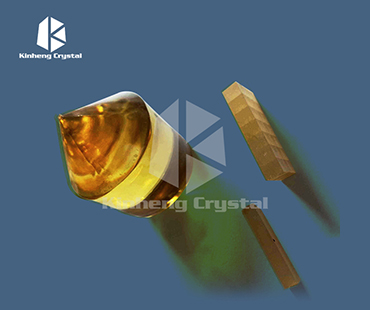

In the rapidly evolving world of technology, sapphire wafers have emerged as a cornerstone for innovation across various industries. As manufacturers seek durable, high-performance materials to enhance their product offerings, sapphire wafers stand out due to their exceptional strength, thermal conductivity, and optical clarity. These properties make them an ideal choice for applications ranging from telecommunications to consumer electronics and even medical devices. As we look forward to 2025, it is clear that sapphire wafers will play a pivotal role in driving advancements in these sectors. The unique characteristics of sapphire, a crystalline form of aluminum oxide, enable it to sustain extreme conditions while providing high-quality performance. This makes sapphire wafers indispensable in applications that require reliability and longevity. As the demand for efficient, high-performance materials increases, companies are encouraged to explore how sapphire technology can be integrated into their products. By prioritizing innovation and investing in sapphire wafers, manufacturers can not only meet current market demands but also pave the way for future advancements. For global buyers seeking to leverage cutting-edge materials, sapphire wafers present an unparalleled opportunity. The commitment to continuous improvement and adaptation in response to market needs positions sapphire technology as a crucial component for businesses aiming for sustainable growth and competitiveness. As we approach 2025, investing in sapphire wafers is not just a strategic move; it’s a step toward embracing a more innovative, resilient, and technologically advanced future.

Sapphire Wafer Is The Best Where Innovation Meets 2025

| Dimension | Material Type | Thickness (mm) | Application | Innovation Feature |

|---|---|---|---|---|

| 2" (50.8 mm) | Sapphire | 0.5 | LED Technology | High Thermal Conductivity |

| 4" (100 mm) | Sapphire | 1.0 | Laser Diodes | Enhanced Durability |

| 6" (150 mm) | Sapphire | 1.5 | Electronic Devices | Superior Optical Clarity |

| 8" (200 mm) | Sapphire | 2.0 | Optoelectronics | High Resistance to Scratches |

Related Products