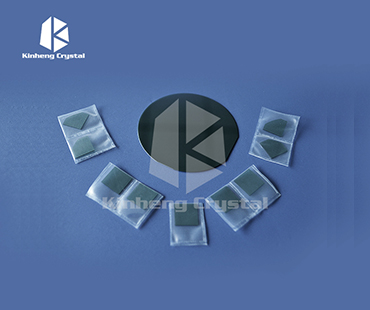

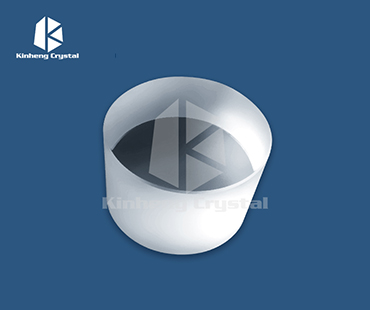

High-Quality Calcium Fluoride Wafer from Reliable Supplier

When it comes to sourcing high-quality Calcium Fluoride Wafers, I understand the critical role that dependable suppliers play in your production process. Our Calcium Fluoride Wafers are crafted with precision, ensuring excellent optical clarity and low absorption rates, making them perfect for various industrial applications. I take pride in offering a product that meets rigorous quality standards while remaining competitively priced. Whether you are in electronics, optics, or any research field, our wafers deliver the reliability and performance you need. Choosing me as your supplier means you’re guaranteed not just a product, but a partnership that values your success. I'm here to assist you with any specific requirements and make sure you receive the best service possible. Let's collaborate to elevate your projects with our superior Calcium Fluoride Wafers.

Calcium Fluoride Wafer For the Current Year Now Trending

In the rapidly evolving semiconductor industry, calcium fluoride wafers have become a hot topic for global buyers this year. These wafers, known for their excellent optical and thermal properties, are increasingly used in various applications such as lasers, optics, and even in high-performance electronics. The demand for high-purity calcium fluoride wafers is soaring, driven by advancements in photonic devices and the need for reliable materials in cutting-edge technologies. As manufacturers strive to meet this demand, the focus has been on enhancing the quality and uniformity of calcium fluoride wafers. This involves meticulous selection of raw materials and advanced production processes to ensure that each wafer meets the stringent requirements of modern applications. Buyers are now more inclined to seek suppliers who can provide comprehensive technical support alongside high-quality products, allowing them to optimize their processes and reduce time to market. Navigating the procurement of calcium fluoride wafers requires a keen understanding of market trends and supplier capabilities. With the increased interest in sustainable manufacturing, buyers are also looking for partners committed to environmentally friendly practices. As the global landscape continues to shift, staying informed about the latest developments and innovations in the calcium fluoride sector will empower buyers to make strategic decisions that align with their business goals.

Calcium Fluoride Wafer Trending Data for 2023

| Parameter | Value | Unit |

|---|---|---|

| Thickness | 0.5 | mm |

| Diameter | 100 | mm |

| Transmittance | 95 | % |

| Crystal Structure | Cubic | - |

| Density | 3.18 | g/cm³ |

| Usage | Optical Coatings | - |

Related Products