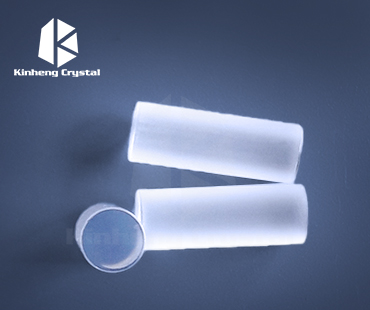

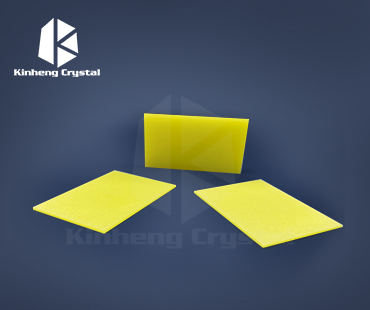

Premium Single Crystal Substrates with CE Certification from Trusted Factory

As a supplier of premium single crystal substrates, I understand how crucial quality is for your projects. These substrates are meticulously crafted to meet precise specifications, ensuring exceptional performance in your applications. Our products are not only resistant to contamination but also exhibit excellent uniformity, essential for cutting-edge technology solutions. When it comes to assurance, I prioritize compliance with CE certification, so you can be confident in the reliability and safety of our substrates. Our factory uses advanced manufacturing techniques, enabling us to maintain strict quality control throughout the production process. I invite you to explore our range and see how our single crystal substrates can enhance your projects. Let’s connect to discuss your specific needs and how we can support your business with high-quality substrates. Quality, reliability, and excellence are what I strive to deliver for you.

Single Crystal Substrates Is The Best Custom Solutions,

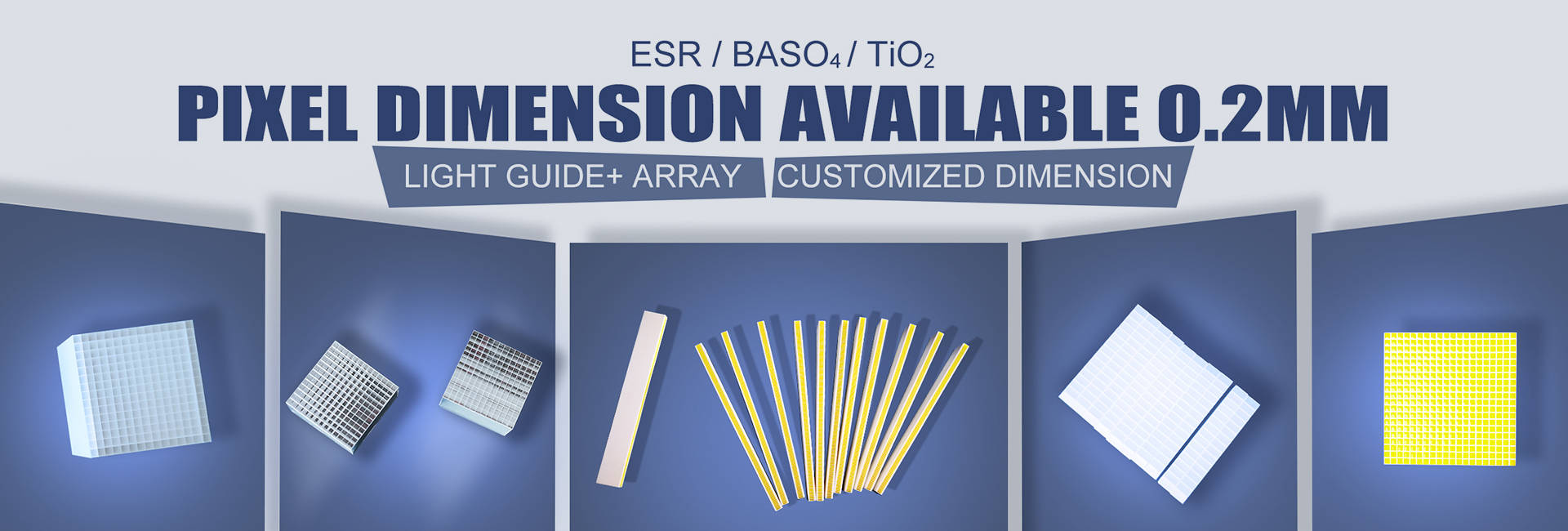

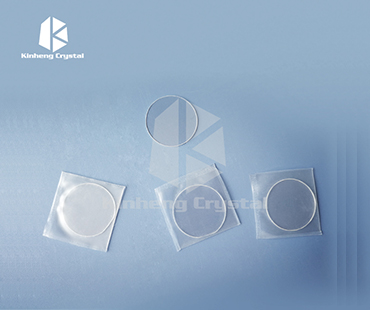

In the ever-evolving landscape of technology and materials science, single crystal substrates have emerged as a premier choice for advanced applications in various industries, including electronics, optoelectronics, and photonics. These substrates are crafted to provide unparalleled purity and crystalline quality, making them indispensable for the fabrication of high-performance devices. Tailored to meet specific requirements, custom solutions in single crystal substrates allow manufacturers to achieve optimal performance tailored to their unique applications. The versatility of single crystal substrates is a key advantage for global buyers. Whether you require substrates with precise dimensions, specific doping levels, or unique surface characteristics, custom solutions are available to address diverse project needs. By partnering with expert suppliers specializing in single crystal materials, businesses can ensure a reliable supply chain, enhanced material properties, and superior manufacturing efficiency. Investing in high-quality substrates not only leads to improved product performance but also paves the way for innovation, enabling companies to stay competitive in a rapidly changing market. As industries continue to push the boundaries of technology, the demand for high-quality single crystal substrates is set to increase. Embracing custom solutions allows companies to leverage advanced materials to develop cutting-edge applications, ensuring they can meet the challenges of tomorrow. By understanding the importance of selecting the right substrates, global purchasers can make informed decisions that will ultimately drive their business success.

Single Crystal Substrates Is The Best Custom Solutions

| Material Type | Crystal Structure | Orientation | Size (mm) | Application |

|---|---|---|---|---|

| Silicon | Diamond Cubic | (100) | 100 x 100 | Semiconductors |

| Gallium Nitride | Wurtzite | (0001) | 50 x 50 | LEDs |

| Sapphire | Hexagonal | (1120) | 2 inch | Optoelectronics |

| Lithium Niobate | Triclinic | (001) | 25 x 25 | Photonics |

| Zinc Oxide | Wurtzite | (0001) | 100 x 100 | Sensors |

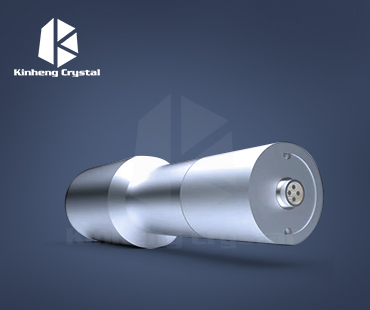

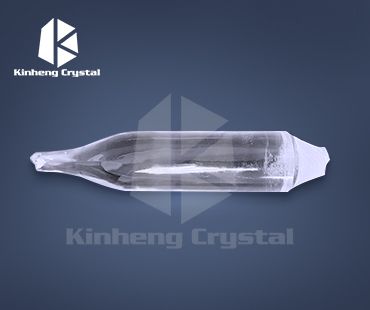

Related Products